- Joined

- Aug 20, 2013

- Messages

- 20

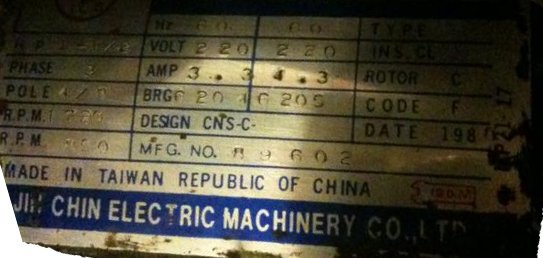

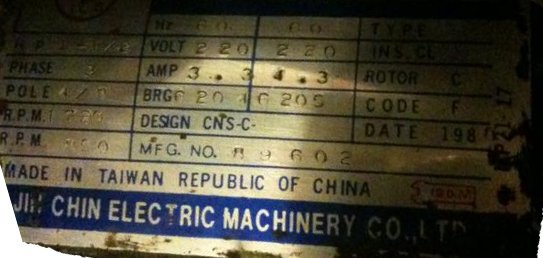

I think I have this right, but it's always best to check before applying power. I am trying to wire up a two speed 6 wire 3 phase motor to run at it's highest speed.

Below is the motor data plate and what's left of the wiring diagram.

I believe I need to wire U1, V1, W1 to power and leave U2, V2, W2 disconnected. Please let me know if I'm right or wrong.

Also, for programming the VFD, the highest speed setting would mean using 2 pole, 4.3 amps, and 1720 RPM?

Thanks !

Below is the motor data plate and what's left of the wiring diagram.

I believe I need to wire U1, V1, W1 to power and leave U2, V2, W2 disconnected. Please let me know if I'm right or wrong.

Also, for programming the VFD, the highest speed setting would mean using 2 pole, 4.3 amps, and 1720 RPM?

Thanks !