-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model Engine

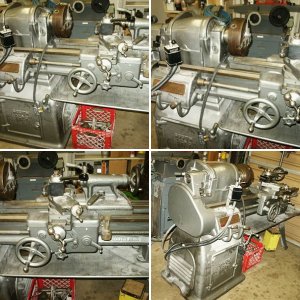

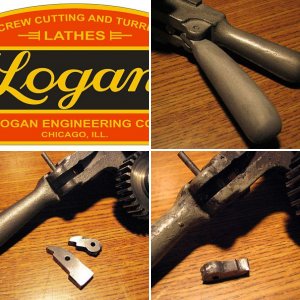

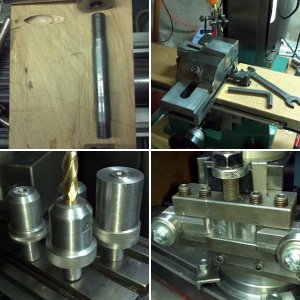

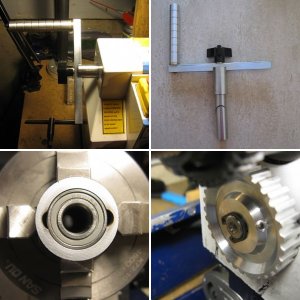

Scraping in all bearing surfaces on my Wards/Logan 10"

PIN

- 39,492

- 73

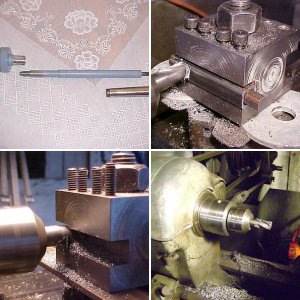

I've been working on my lathe off and on over the past several weeks or months, but I've been hesitant to start a thread documenting my progress (or lack thereof!) for fear of embarrassing myself. I'm increasingly confident that I'm going to end up with a very precise lathe rather than a very large pile of cast iron dust and tears, so I'm finally willing to share my progress. After creating...

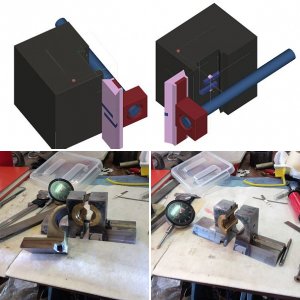

KO-Lee Cutter/Grinder Revamp

PIN

- 30,903

- 93

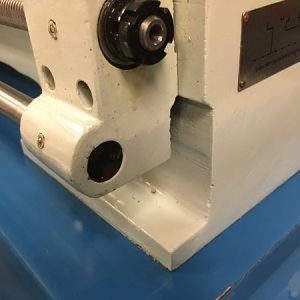

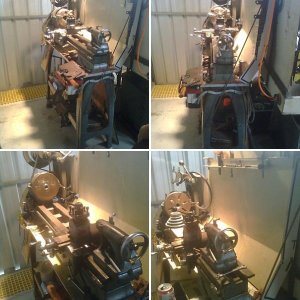

Perhaps you've seen this from other photos... It's a KO-Lee cutter grinder. It's a good platform and the table and all mechanisms are in excellent condition. I don't think this machine was used much in it's lifetime as there are very few signs of wear (hardly any at all really). The motor is the weak link. The bearings are going bad and vibration can be felt in the short shaft. The...

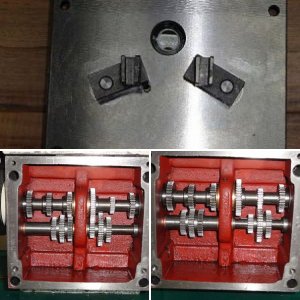

Restoring an old powered hacksaw

Jul 29

- 22,349

- 68

Figured I'd share my restoration project! I've always found these old machines quite cool and when a neighbour offered me a defective one for free, I couldn't say no!  This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

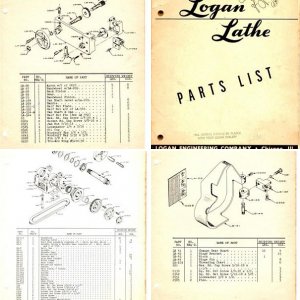

9A project completed

Sep 11

- 34,128

- 66

Some of you guys may remember this little crudball I acquired back in April... I had just completed the last project, the Seneca Falls #30 resto-mod,(project of the month) when this lathe found it's way to me via a friend of a friend. My friend, who is also a tool salesman, showed me a pic of this on his phone, which came from his friend, the seller, who now is a retired tool room...

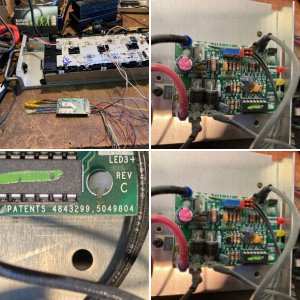

Clausing 1771 Drill Press Restoration

Dec 23

- 22,784

- 31

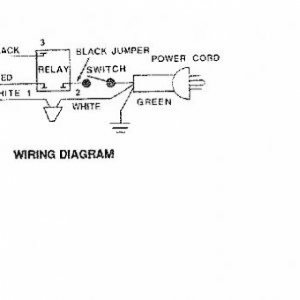

I picked up a Clausing variable speed drill press from a Craigslist ad. I offered the guy $200.00 and he accepted. The drill press was in decent overall condition, and had a new motor on it. I disassembled the machine and cleaned up and painted everything. Mechanically, it was in very good condition, and the only real repair work I did was to straighten a few of the handle arms. One...

Two Timer Build

PIN

- 19,705

- 119

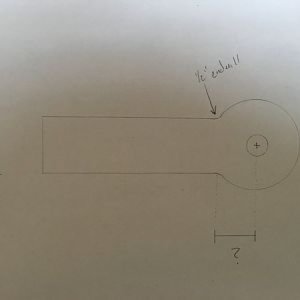

After I finished my crankshaft build last week I asked for ideas of an engine to build around it. There were no replies except for this. At least you know how many cylinders.  Robert Yes thank you Robert I was thinking along those lines myself. I don't know what this engine will turn out to look like but I want to show off the crankshaft so area will be open. I want to try my hand at...

Robert Yes thank you Robert I was thinking along those lines myself. I don't know what this engine will turn out to look like but I want to show off the crankshaft so area will be open. I want to try my hand at...

Edwards Radial 5 build thread --- PHOTOS!

PIN

- 95,265

- 304

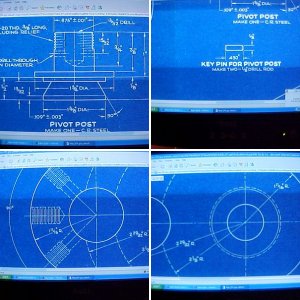

Episode 1 || Introduction to My Build Thread Background After a brief search through the H-M.com archives, I was a bit surprised that nobody had documented their journey building an Edwards Radial 5-cylinder engine. These engines are reasonably complex and time consuming to construct, but as (1) detailed drawings are freely available and (2) it's a 'billet engine' requiring no castings, it...

1/6th scale 1890's 30ft navy steam cutter (live steam)

PIN

- 29,953

- 243

this project started 10 years back when I found the plan book for navy boats 1900,, 2 years ago I came in contact with a full scale steam expert who had the engine and engineering plans.. the 30ftr and 1/6th scale was decided on because a Stuart Turner compound twin engine block is very very close in size.. brass lost wax castings have been completed to convert the ST engine kit to the navy...

My Jeroen Jonkman’s Stirling 60 brass Stirling engine build

PIN

- 13,343

- 30

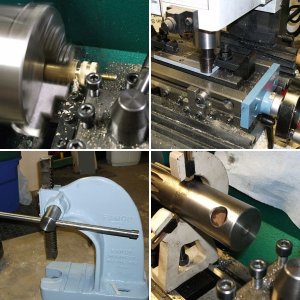

The raw materials... Used a Dremel type diamond cut off wheel to cut the Pyrex test tube to the required length. Some fun with the rotary table. One of the first things I did was make this plate to hold some of these small parts. These adjustable parallels were just the right size to add some support. Cut these 0.047" diameter pins by taking a heavy, single cut. You lose a...

Metal Lathe Accessories is Here to Stay!

Jan 04

- 100

- 4

Hi Everyone, My name is Jared Pilch (Co-Owner of Metal Lathe Accessories) and I sent out the below mass email to as many of our MLA customers as I could find. However, I am sure that I missed some and that is why I am posting it here as well! My bother Jack and I are thrilled to have joined this community and look forward to learning as much as we can! As some of you are aware, Andy...

First Project - Upshur's Model Farm Engine

Feb 11

- 7,169

- 10

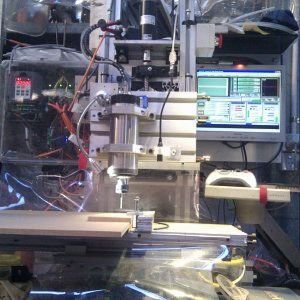

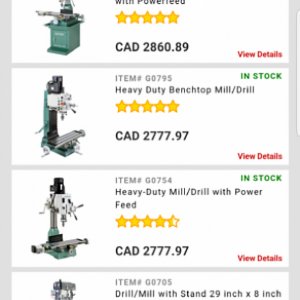

I am a retired software engineer and back a year ago I got the itch to learn how to precisely cut metal. You know, build something that I could actually touch and see. Around mid June I got delivery of my PM-1030V lathe with DRO and a bunch of tooling. This was followed in mid December of the arrival of a PM-727V mill, also with DRO, and more tooling. After dickering with setup, alignment and...