- Joined

- Sep 19, 2012

- Messages

- 3,063

The back story.

I have a Francis Reed drill press that I have been tinkering with for a few months now.

The previous owner used a bolt that had been roughly ground down to resemble a MT#2 by hand to hold the chuck in place.

He fought with it, and tried to drive his home made taper into place with a BFH, and he also confessed that it had spun in the socket numerous times.

In frustration he sold it to me.

I pulled the shaft and centered it in the 4 jaw and took a skim cut to clean it up a bit.

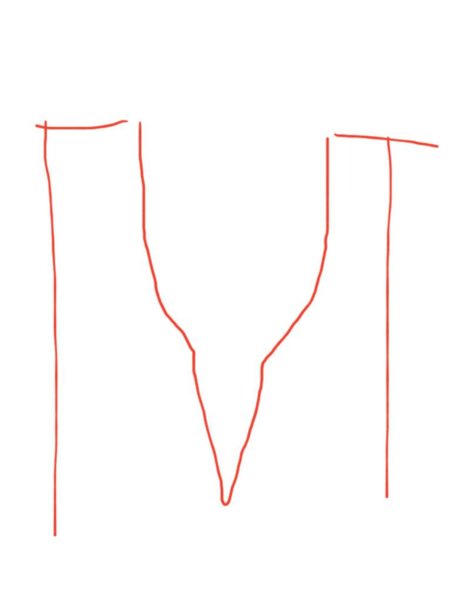

I checked the socket with a MT2 drill adapter, and found that the socket is shaped similar to this.

The socket is not long enough to re-ream the hole, so a MT2 is out of the equation.

I do have a MT3 reamer, but the shaft is not big enough in diameter for a MT3.

Could I make a sleeve and silver solder it onto the end of the shaft to add to the diameter?

Should I thread and locktight on a sleeve?

Should I just wheel it out to the curb and tell y'all where it is?(sarcasm!)

What do y'all think?

Sent from my SM-S320VL using Tapatalk

I have a Francis Reed drill press that I have been tinkering with for a few months now.

The previous owner used a bolt that had been roughly ground down to resemble a MT#2 by hand to hold the chuck in place.

He fought with it, and tried to drive his home made taper into place with a BFH, and he also confessed that it had spun in the socket numerous times.

In frustration he sold it to me.

I pulled the shaft and centered it in the 4 jaw and took a skim cut to clean it up a bit.

I checked the socket with a MT2 drill adapter, and found that the socket is shaped similar to this.

The socket is not long enough to re-ream the hole, so a MT2 is out of the equation.

I do have a MT3 reamer, but the shaft is not big enough in diameter for a MT3.

Could I make a sleeve and silver solder it onto the end of the shaft to add to the diameter?

Should I thread and locktight on a sleeve?

Should I just wheel it out to the curb and tell y'all where it is?(sarcasm!)

What do y'all think?

Sent from my SM-S320VL using Tapatalk

Last edited: