- Joined

- Dec 27, 2014

- Messages

- 4,055

I cant help but think its probably not ideal for that (milling on the edge).

That's why its' called a "Face" mill.

I cant help but think its probably not ideal for that (milling on the edge).

At least 1/16" gap between the low and the high. Plus there was a huge difference in cutting diameter. I'm guessing about 1/8".

At least 1/16" gap between the low and the high. Plus there was a huge difference in cutting diameter. I'm guessing about 1/8".

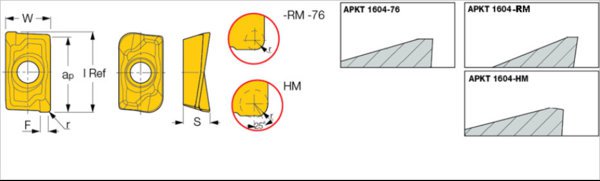

Were they these same (APxx 1604) inserts or something different? I have to think the pockets themselves control 99% of the insert height relative to cutting plan datum. Maybe there is a way you can get a DTI in the top corner of each pocket to compare. If that checks out, then maybe the screw hole is low & drawing the insert down? (but you would visibly see a gap on top of insert).

Just a thought, have you calipered the inserts themselves to see if they are identical? If for example you had different nose radii other geometric feature, would that account for different contact height? I really don't know how these are designed. Maybe the contact position is supposed to be identical. Or maybe the parallelogram is the same but a larger nose radius would effectively shorten the height?