- Joined

- Jul 2, 2014

- Messages

- 7,594

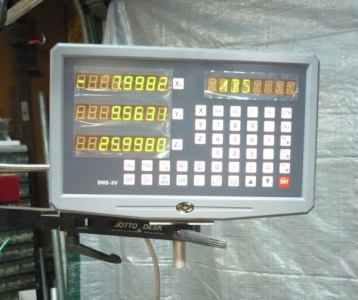

Thank you. Boy, those don't look like mine do they?Here ya' go!

Mine "look" like they might actually fit...Thank you. Boy, those don't look like mine do they?

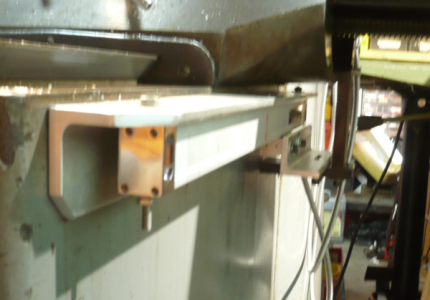

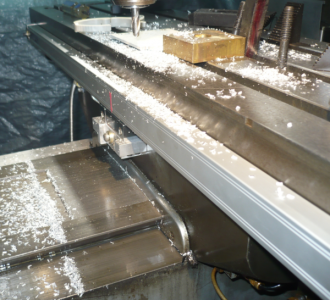

My idea is to use 1 x 1 x 1/8" aluminum channel.I think the aluminum angle on the 'Y' mount works well as a chip guard, per BobK's idea in another thread.

Design Review Meeting, 3:10pm EDTMy idea is to use1 x 1 x 1/8"1.25" x 1.25" x 1/8" aluminum channel.

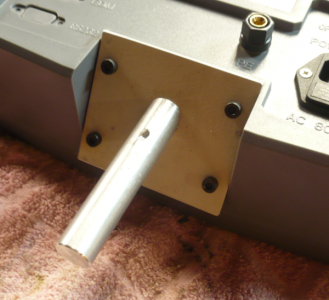

I am sorry, Dan. It was 1 1/4" that I was hoping to use. 1" inside dimensions. I did get the "slim" scale for the X axis, it is a little less tall, but the same width as the standard scales (no extra cost). The end caps of the slim scales are about 21 x 29 mm. Also considering attaching the scale to the outer flange of the channel, and the channel separately to the table. Open side of the channel facing down. It will probably require some rubber or other flexible material added to the outside leg of the channel to adequately keep the chips and oil out of the scale. I do think it would give the scale a lot more protection. I am putting the X scale at the front of the table, not the rear.Design Review Meeting, 3:10pm EDT

Didn't you get the same scales as I have? I don't think 1x1 will work. or I'm missing the obvious.

Quick layout sketch. Which technically do not believe their 21.5mm dimension. My end caps measured .866"/22mm.

View attachment 262900