-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to find the taper angle of a (sliced) cone

- Thread starter stioc

- Start date

- Joined

- Feb 1, 2015

- Messages

- 9,574

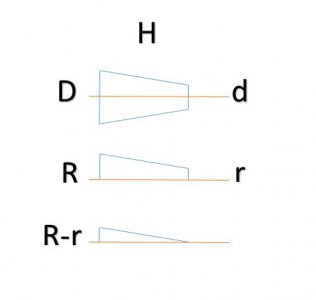

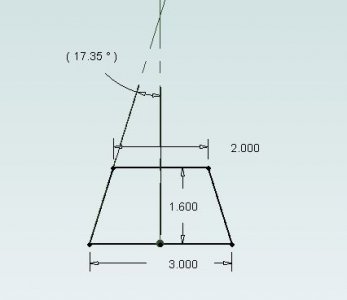

The taper is the difference in diameters divided byr the distance separating them but the half angle (measured between center line and the taper is the arctan of half the taper. The total include angle is twice that angle. Taking the arctan of the taper is close to the total angle but only when the angle is small. For small angle measured in radians, a = tan a = sin a. As the angle increases this equality falls a part. For example , for a 1º angle a = .017453 radians, tan a = .0174655, and sin a = .017452 but for a 45º angle a = .7854 radians, tan a =1, and sin a =.7071. For this reason the equality a = 2 arctan a/2 is not true.Measure the small diameter. Big diameter minus small diameter divided by taper length. The tangent of this number is your angle.

- Joined

- Nov 16, 2012

- Messages

- 5,596

OP here...per post# 13 above I was able to calculate and verify the correct angle using the ArcTan(R-r/H) forumla.

Ray you're absolutely correct...however, the dimensions I used in this thread were not the actual dimensions of the cone though, hence my results in post #13 were different but the formula was spot on. Thank you and everyone else for that.

Ray you're absolutely correct...however, the dimensions I used in this thread were not the actual dimensions of the cone though, hence my results in post #13 were different but the formula was spot on. Thank you and everyone else for that.

- Joined

- Feb 1, 2015

- Messages

- 9,574

Mark, There were two errors in your previous post. The first is that to find the angle, you use the arctangent function not the tangent. The second is that you have to use the radii rather than the diameters to determine the angle as stated by Ray in posts 6 & 9. arctan(D/2-d/2)/H = arctan(.5/1.6) =17.354º while (arctan(D-d)/H/2 = 16.00º.Rj for this example the proper trig function is tangent. Opposite over ajacent. It will give you the included angle. As accurate as can be!

edit: added missing divide by 2

Last edited:

You guys are absolutely right! I am doing my compound setting using taper per foot. Heres what I was thinking. Taper foot is tpf over 24 equals tangent angle. Or not really thinking at all I guess Thanks guys learn something everyday and realize just how much I need to hit the books again. Been away some twenty years after doing for it for twenty. Started in screw machines while doing and app. Program doing general machining. Took a job across country as a general machinist. Not enough work and life. Driven a Zambonii for the last twenty in another town now for work. Lost some people in my life. Realized i miss machining. Seeing something your making evolve. Good for the soul. Sold my two motorcycles and took out the credit card and back into machining at fifty. Still driving a zamboni for now. I Can ramble a bit! But guys I am not too proud and Always willing to learn. Thanks And another realization there is so much and machining is definite. No Horseshoes! Need to sharpen up I guess. Just another great challenge on it s own to learn and be interested!