- Joined

- Feb 13, 2012

- Messages

- 60

I have repaired small engines for over fifty years.

Now I mainly work on small two stroke equipment.

Some time back, I bought a Tanaka chainsaw that would not oil the chain. I discovered the plastic drive gear was damaged and only available with complete pump assembly and was over $140.00 !

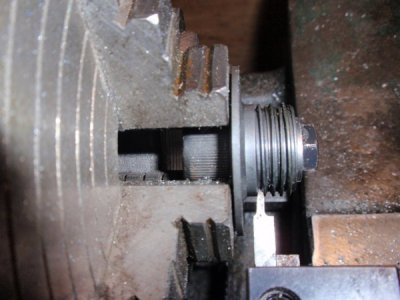

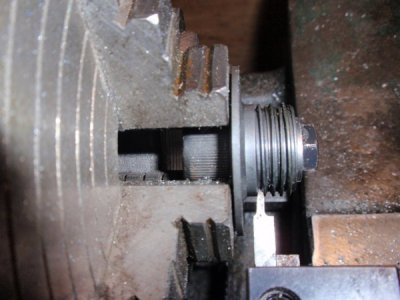

Upon inspection, I decided to try an repair plastic worm gear. I had other photos but can't find them. Only photo shows specially ground bit picking up thread profile and pitch.

I made an aluminum gear and pressed it onto the plastic assembly after removing damaged outer thread.

Still working beautifully!

It took a lot of figuring and close machining, but it worked beautifully.

Now I mainly work on small two stroke equipment.

Some time back, I bought a Tanaka chainsaw that would not oil the chain. I discovered the plastic drive gear was damaged and only available with complete pump assembly and was over $140.00 !

Upon inspection, I decided to try an repair plastic worm gear. I had other photos but can't find them. Only photo shows specially ground bit picking up thread profile and pitch.

I made an aluminum gear and pressed it onto the plastic assembly after removing damaged outer thread.

Still working beautifully!

It took a lot of figuring and close machining, but it worked beautifully.