-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tumblers & Media

- Thread starter jbolt

- Start date

- Joined

- Feb 27, 2014

- Messages

- 2,124

I use a drum tumbler and not a vibratory tumbler and I have no idea if this will transfer to a vibratory tumbler or not but it might still might give you a place to start

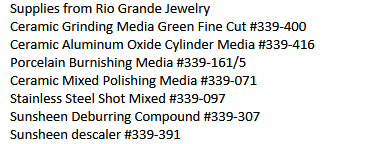

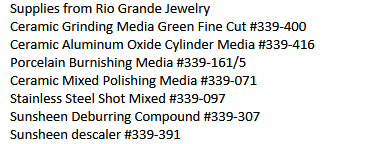

here is the BOM of Media and solutions

I typically run 4 steps

Step1: 4 hours with Deburring compound and Green Fine Cut

Step 2: 4 hours with deburring compound and Aluminum Oxide

Step 3: 4 hours with Deburring compound and Mixed Polishing Media

Step 4: 5 hours with Descaler and Stainless steel mixed shot

This gives a more polished result so for a more Matt finish you might leave out step 4. Bottom line is to experiment. Also depending on the shape of the part you are making you may need to adjust the size and shape of the Media so they don't get stuck in hard to get places.

Again, experiment with times and media to get the finish that you are looking for.

here is the BOM of Media and solutions

I typically run 4 steps

Step1: 4 hours with Deburring compound and Green Fine Cut

Step 2: 4 hours with deburring compound and Aluminum Oxide

Step 3: 4 hours with Deburring compound and Mixed Polishing Media

Step 4: 5 hours with Descaler and Stainless steel mixed shot

This gives a more polished result so for a more Matt finish you might leave out step 4. Bottom line is to experiment. Also depending on the shape of the part you are making you may need to adjust the size and shape of the Media so they don't get stuck in hard to get places.

Again, experiment with times and media to get the finish that you are looking for.

- Joined

- Feb 8, 2014

- Messages

- 11,144

If the parts are somewhat small this works well, I have run mine for hours and hours.

https://www.harborfreight.com/18-lb-vibratory-bowl-with-liquid-drain-hose-96923.html

And for media

https://www.harborfreight.com/540-lbs-medium-ceramic-abrasive-polishing-tumbler-media-63673.html

https://www.harborfreight.com/18-lb-vibratory-bowl-with-liquid-drain-hose-96923.html

And for media

https://www.harborfreight.com/540-lbs-medium-ceramic-abrasive-polishing-tumbler-media-63673.html

- Joined

- Jun 7, 2013

- Messages

- 10,070

For a matt finish, why not bead blast?

- Joined

- Dec 3, 2013

- Messages

- 1,844

It's on my list for when we move and I have a shop with more space. Currently I don't have room at this time for a blast cabinet. I can squeeze in a tumbler.For a matt finish, why not bead blast?

- Joined

- Dec 3, 2013

- Messages

- 1,844

I use a drum tumbler and not a vibratory tumbler and I have no idea if this will transfer to a vibratory tumbler or not but it might still might give you a place to start

here is the BOM of Media and solutions

View attachment 280873

I typically run 4 steps

Step1: 4 hours with Deburring compound and Green Fine Cut

Step 2: 4 hours with deburring compound and Aluminum Oxide

Step 3: 4 hours with Deburring compound and Mixed Polishing Media

Step 4: 5 hours with Descaler and Stainless steel mixed shot

This gives a more polished result so for a more Matt finish you might leave out step 4. Bottom line is to experiment. Also depending on the shape of the part you are making you may need to adjust the size and shape of the Media so they don't get stuck in hard to get places.

Again, experiment with times and media to get the finish that you are looking for.

What does the duburring compound do that a detergent wouldn't?

- Joined

- Dec 3, 2013

- Messages

- 1,844

Is the ceramic media harsh on aluminum? Do you run wet with soap or detergent?If the parts are somewhat small this works well, I have run mine for hours and hours.

https://www.harborfreight.com/18-lb-vibratory-bowl-with-liquid-drain-hose-96923.html

And for media

https://www.harborfreight.com/540-lbs-medium-ceramic-abrasive-polishing-tumbler-media-63673.html

- Joined

- Feb 27, 2014

- Messages

- 2,124

What does the duburring compound do that a detergent wouldn't?

the short answer is that "I don't know" This process was handed down to me and I have not tried to fix what is not broke. I have thought from time to time about what the difference in the two different SunSheen liquids are. They both feel like dishwashing soap

- Joined

- Dec 3, 2013

- Messages

- 1,844

Okay thanks. Back in my machine shop days we used Palmolive as a detergent in the drum tumbler. I' can't recall what we used for media other than getting chewed out for running it too long. Ahh the days when employers could yell at, threaten and berate their employees.the short answer is that "I don't know" This process was handed down to me and I have not tried to fix what is not broke. I have thought from time to time about what the difference in the two different SunSheen liquids are. They both feel like dishwashing soapand could be just expensive soap. I mix just a small amount (couple of tablespoons) to 3/4 gallon of water so what ever they are, there is not much of it.

- Joined

- Oct 3, 2015

- Messages

- 982

https://www.harborfreight.com/catal...e,f,EAFeatured+Weight,f,Sale+Rank,f&q=tumbler

This is what you want for aluminum, the little green pyramids. You must run it wet or it will turn black and glaze over. I use water and ivory dish soap in a recirculating pump.

This is what you want for aluminum, the little green pyramids. You must run it wet or it will turn black and glaze over. I use water and ivory dish soap in a recirculating pump.