- Joined

- Apr 23, 2014

- Messages

- 40

My Lathe, my 6" LATHE! Come on guys, get your minds out of the gutter... (this is one of those times I really wish I had a 12")

Anyway, I've got an old Craftsman 101.21400 that I picked up a few years ago. I have made a few things with it but I don't have much tooling and there are some issues with it that I have been wanting to rectify but haven't gotten around to it, until now. One of the biggest things that has bothered me is some horrible backlash in the cross slide. There was a cross slide screw and nut on ebay that looked like it was in good shape so I bought it. I am pretty sure it was brand new, at least it looked like it had VERY little wear. Here it is compared to my old screw.

No wonder it was bothering me so much! The new screw feels so much better!

One question though, does the dial need to be in a certain position on the screw? I didn't make note of where the old dial was before I removed it but I put the new one on so that the 0 mark was in line with the woodruff key for the hand wheel. I also need to make a new nut that goes on the end to hold the hand wheel on. I could buy a new one but they are about $20 and I figure I could just buy a tap and turn my own nut.

One other thing that has bothered me (and may be part of the reason for the wear on the cross slide screw) is that the lathe was missing the chip guard that mounts on the cross slide, so I bought one and mounted it. Having that on gives me some nice warm fuzzies, especially with that new screw in there.

I also bought a thread dial since I plan to do some thread cutting and my lathe didn't have one.

The lathe is currently set up without the countershaft, it just has a motor mounted behind the headstock with a belt straight to the spindle pulleys. The motor has a pulley with 4 positions so I still have a few different speeds but I would still like to get the countershaft set up how it should be.

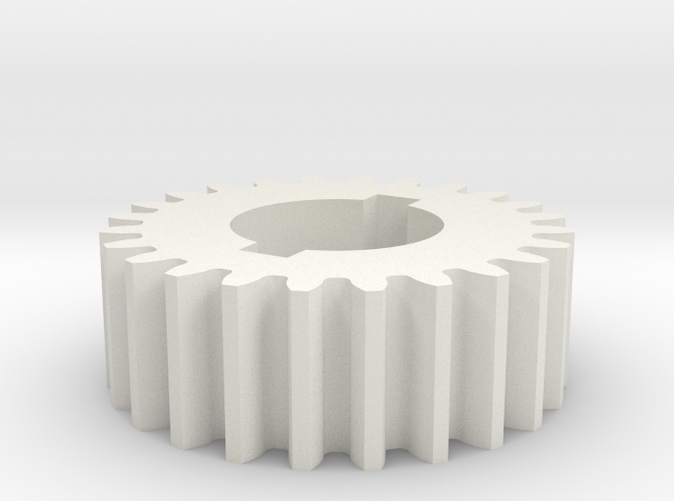

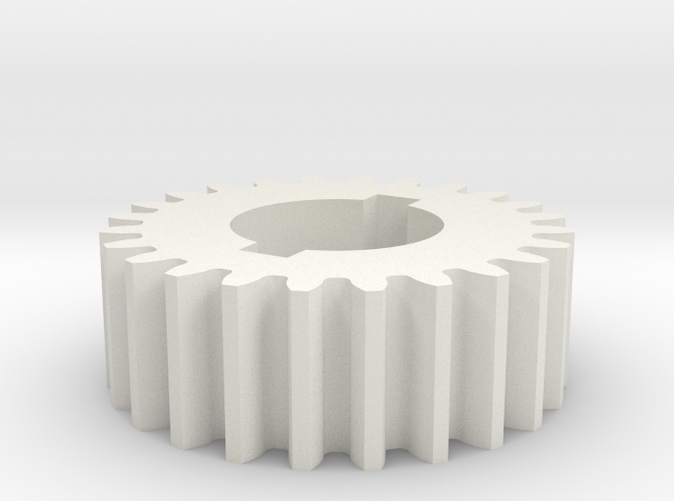

I also noticed I was missing a 24 tooth change gear so I modeled one up in 3d and had it printed through Shapeways. It turned out pretty good, we will see how long it holds up. Here it is on Shapeways:

www.shapeways.com

www.shapeways.com

Thats pretty much it for now. I'll take a picture ofmy 6" the lathe as soon as I get it cleaned up a bit more, it is pretty messy right now.

Anyway, I've got an old Craftsman 101.21400 that I picked up a few years ago. I have made a few things with it but I don't have much tooling and there are some issues with it that I have been wanting to rectify but haven't gotten around to it, until now. One of the biggest things that has bothered me is some horrible backlash in the cross slide. There was a cross slide screw and nut on ebay that looked like it was in good shape so I bought it. I am pretty sure it was brand new, at least it looked like it had VERY little wear. Here it is compared to my old screw.

No wonder it was bothering me so much! The new screw feels so much better!

One question though, does the dial need to be in a certain position on the screw? I didn't make note of where the old dial was before I removed it but I put the new one on so that the 0 mark was in line with the woodruff key for the hand wheel. I also need to make a new nut that goes on the end to hold the hand wheel on. I could buy a new one but they are about $20 and I figure I could just buy a tap and turn my own nut.

One other thing that has bothered me (and may be part of the reason for the wear on the cross slide screw) is that the lathe was missing the chip guard that mounts on the cross slide, so I bought one and mounted it. Having that on gives me some nice warm fuzzies, especially with that new screw in there.

I also bought a thread dial since I plan to do some thread cutting and my lathe didn't have one.

The lathe is currently set up without the countershaft, it just has a motor mounted behind the headstock with a belt straight to the spindle pulleys. The motor has a pulley with 4 positions so I still have a few different speeds but I would still like to get the countershaft set up how it should be.

I also noticed I was missing a 24 tooth change gear so I modeled one up in 3d and had it printed through Shapeways. It turned out pretty good, we will see how long it holds up. Here it is on Shapeways:

24T Atlas 618/Craftsman 101 Change Gear by dlduncan on Shapeways

Check out 24T Atlas 618/Craftsman 101 Change Gear by dlduncan on Shapeways and discover more 3D printed products in Mechanical Parts.

Thats pretty much it for now. I'll take a picture of