Just picked up myself a nice winter project. A Lagunmatic.

I have 0 CNC experience. So this will be a good challenge.

Currently has Fagor 8010m controller. Doesnt really want to turn on. I plan on upgrading to PC anyway. I kept my old gaming computer around for just such a project.

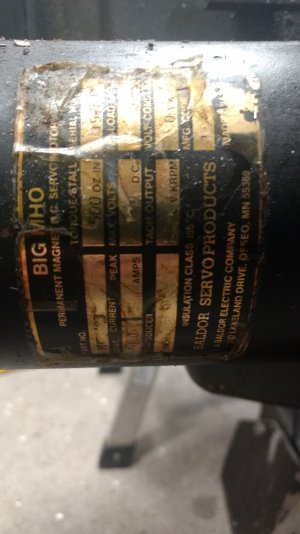

The lagun has dc brushed servo motors currently on X,Y,Z and they all work. When I powered up the machine, they all worked. So thats a plus. Maybe the Fagor controller didnt like running off a RPC?. There is no manual with this, and no labels to what input for what the machine needs to be wired to. Machine is overall in great shape, just needs a super bath from siting in the corner for so many years neglected.

I have no idea what I need to run this off my pc . Ive only seen a handful of youtube and reading around here. I need a breakout board? some drive controlers? Mach4 or Linuxcnc, thats it? Seems pretty simple compaired to trying to figure out whats wrong with the Fagor controller. Id say Im ok when it comes to building computers but, trouble shooting old circut boards or monitors doesnt seem like fun. Not to mention that I could probably figure out Mach4 or LinuxCNC software easier than learing the Fagor Controller. Not to mention the fagor controller is about the same size of the mill! lol It would be nice just have have a small computer and monitor mounted to the side.

. Ive only seen a handful of youtube and reading around here. I need a breakout board? some drive controlers? Mach4 or Linuxcnc, thats it? Seems pretty simple compaired to trying to figure out whats wrong with the Fagor controller. Id say Im ok when it comes to building computers but, trouble shooting old circut boards or monitors doesnt seem like fun. Not to mention that I could probably figure out Mach4 or LinuxCNC software easier than learing the Fagor Controller. Not to mention the fagor controller is about the same size of the mill! lol It would be nice just have have a small computer and monitor mounted to the side.

My other mill is a full size Grizzly that was converted to cnc, that was non operational. It was advised that I would be better off making it a manual mill instead of messing around trying to figure out all the cnc controls. I kinda regretted that, but now I have a legit CNC that just needs a little help. I have stepper motors (I think) from the Grizzly machine somewhere, if those are better than the dc servo motors? I dont know the size of them, but I'll go find them and look. I dont know the size of motors needed to power a full size mill either.

Ill post some pics when I can.

Any input on breakout boards or drivecontorllers and software is much appreciated.

I have 0 CNC experience. So this will be a good challenge.

Currently has Fagor 8010m controller. Doesnt really want to turn on. I plan on upgrading to PC anyway. I kept my old gaming computer around for just such a project.

The lagun has dc brushed servo motors currently on X,Y,Z and they all work. When I powered up the machine, they all worked. So thats a plus. Maybe the Fagor controller didnt like running off a RPC?. There is no manual with this, and no labels to what input for what the machine needs to be wired to. Machine is overall in great shape, just needs a super bath from siting in the corner for so many years neglected.

I have no idea what I need to run this off my pc

My other mill is a full size Grizzly that was converted to cnc, that was non operational. It was advised that I would be better off making it a manual mill instead of messing around trying to figure out all the cnc controls. I kinda regretted that, but now I have a legit CNC that just needs a little help. I have stepper motors (I think) from the Grizzly machine somewhere, if those are better than the dc servo motors? I dont know the size of them, but I'll go find them and look. I dont know the size of motors needed to power a full size mill either.

Ill post some pics when I can.

Any input on breakout boards or drivecontorllers and software is much appreciated.