Graham -

Thanks for your explanation. I really goofed when I said "monochromator" ... actually meant to ask about way to distinguish the wavelength/energy of the fluorescence (Xray) photons. Your mention of a spectrum analyzer did set me straight. Bottom line, though, is that I'm an old geezer and sometimes kinda dinosaurian in my thinking. Ah, well ...

Old geezer me too, but I nevertheless am still surprised and irritated when the stuff that reminds us of it gets in the way of a bit of "growing old disgracefully".

As I understand it so far..

1. You start with some of these smoke detector sensors. Here is one I extracted from an old smoke detector.

(Yeah - nearly live. On the desk in front of me. Making a mess!)

Not that I expect any Brownie points from HM for doing this in their cause, but I am very aware that I am handling a by-product of plutonium decay that is a fissile material with a large neutron absorption cross section 5700 barns (yes - as in "big as a barn door"), which gives it a critical mass of around 9kg to 14kg. This is not quite what I mean when I say "growing old disgracefully, but you get the idea.

That said, the amount in there is around 2.62E-7g or 262 nano-grams. It is in the little pressed metal setting "button", which comes out and bounces on the desk, and makes it to the floor, and ..yeah!

Of course, the great YT resource shows it much better than I can, and one in particular comes with fun sparks and zap stuff..

-->

How Radiation Works using Americium 241, Alpha Particles and Gamma Rays

and another where at about 3:05, we actually see the radioactivity measured (no gloves)

-->

Extraction of Americium 241 from Smoke Detector

It occurs to me that one might get up an effective source from grinding up a Coleman lamp gas mantle. You can get the thorium version, which work better than the yttrium type as lamps, from eBay.

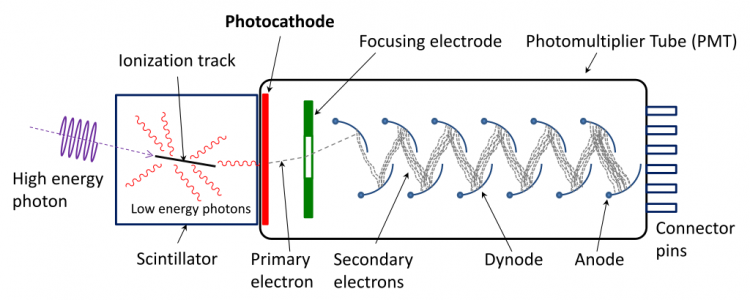

2. We arrange the Am241 buttons in a circle, around a shield tube end. The radiation from the buttons strikes the metal under test, and out comes photons you can't see, back at the detector in the middle of the tube. Yes - the energy that exits the metal atom does have a wavelength, and it might not be at some convenient visible (wavelength).

3. It hits the material of a scintillator material. A crystal of cesium iodide.

They come at all sorts of crazy prices asked, from USA to Ukraine, from 20 bucks to a couple of hundred $$.

Like this --> eBay

CsI

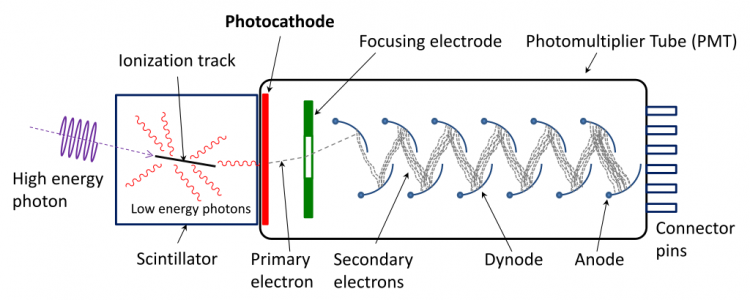

Now we discover there are various scintillation materials, like Na(TI), and every kind of combination fitted up with detector photomultipliers, etc. I have not explored this enough, but know that the electron tube type is the only sort that can get down to the lowest energy detection without generating a lot of competing electrical noise.

The flash given off by the scintillator material is proportional to the photon energy arriving.

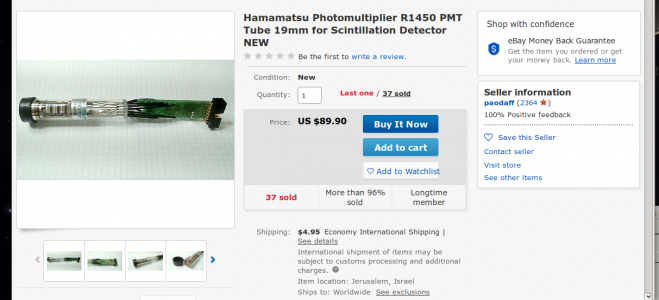

I like the Hamamatsu tube with the cesium iodide scintillator already bonded to the tube.

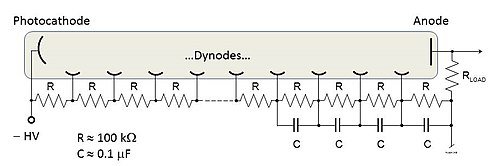

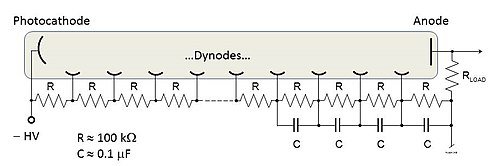

4. The light pulse triggers electrons from a photo-sensitive cathode in a photomultiplier tube. The nature of the thing is to produce in proportion, perhaps up to a hundred million more. An electrical pulse, which can be measured. Clever gadget, but the circuits are simple.

This is, so far, the most expensive part. It is also the place where we get the most variety in DIY approaches. You don't have to get this particular one. The majority of enthusiasts out there are looking to make radiation detectors of various kinds. They want the clicks, and the meter showing the counts per second rate.

What we are after is more subtle. We want to measure the pulse height, duration, and shape.

That is - I think so. Everything I read looks to be about that.

5. If you are still with me so far, this amounts to some fairly simple, and not too expensive kit, given that we are trying to make a nondestructive point-and-shoot general materials detection and analysis gadget.

According to the link from

@RJSakowski , the Wikipedia on Scintillators, you get a pulse. The stuff is very much hard sums about scintillation science, but it is worth scanning even the indigestible , just for perspective.

6.

Measuring the pulse(s).

This is where we need not get all entangled with old project stuff like the "Therimino" thing. I have not yet untangled it all, but it seems they were using the audio input microphone channel on a computer to sample the signal as a 192kHz A-to-D converter, in the same manner as ham radio enthusiasts would contrive to make spectrum and waterfall displays of signals. They also had a PIC micro-controller USB adapter.

I think it is a series of pulses from each scintillation, triggered, sampled, and averaged.

I have not yet figured it all out, but I am thinking that yes - one could use the audio channel as a signal waveform sampler, though my preference would be something more made for the purpose, such as a dedicated A/D converter instrumentation card. Or use the Audio channel. Either way, all you need for final hardware is £35 or so of Raspberry Pi, or Arduino. It could even be a smartphone app.

I freely admit I have not got it all figured out yet, but a steels alloys analysis without breaking the bank seems kind of possible