B

Bill Gruby

Forum Guest

Register Today

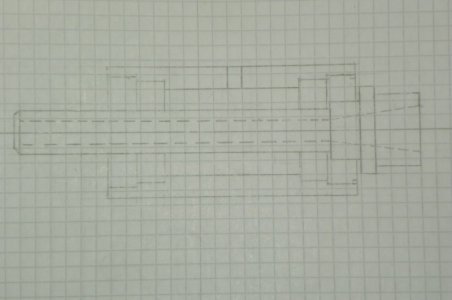

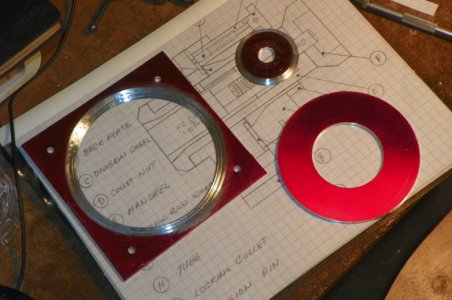

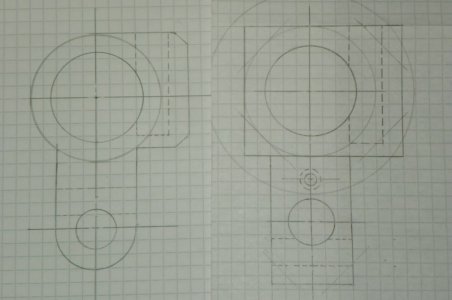

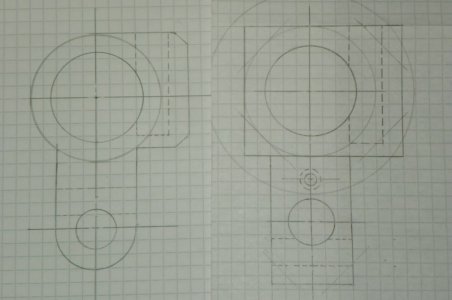

After cutting and setting the tool Holder yesterday I was not happy with the look. It was too bulky and looked even worse. Back to the drawing board. Violla.

The one on the left is what I am going with. Yes, you can make a silk purse out of a Sows Ear. :rofl::rofl::rofl:

This is all I can do till after the Holiday. The War Department say put it to bed for a few days. Translate that to you and I are going to the MALL ( Big Cringe)

"Billy G" )

)

The one on the left is what I am going with. Yes, you can make a silk purse out of a Sows Ear. :rofl::rofl::rofl:

This is all I can do till after the Holiday. The War Department say put it to bed for a few days. Translate that to you and I are going to the MALL ( Big Cringe)

"Billy G"

Last edited by a moderator: