I have been working on this project for quite a while , but keep stopping to make another tool I need. A friend sent me plans he drew up for a small 4 inch manual rotary table he made for his Burke milling machine. I decided to make one for myself. It is fairly simple. I turned a piece of round steel to 4 inches diameter and .875" thick. I then turned a recess to hold some bearings that are on order from McMaster Carr. the recess also holds the rotating part of the table, which I will start on next.

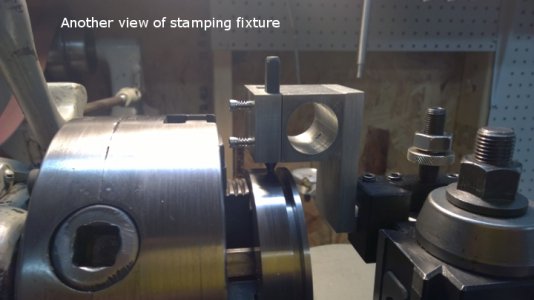

After machining the round to 4 inches diameter, machining the bearing recess, and machining a clamping groove around the bottom, it was time to scribe the degree markings. This is the setup for making the lines. A boring bar with a pointed tool bit, my home made degree wheel mounted on the rear of the spindle, and a way stop to limit the line length.

After machining the round to 4 inches diameter, machining the bearing recess, and machining a clamping groove around the bottom, it was time to scribe the degree markings. This is the setup for making the lines. A boring bar with a pointed tool bit, my home made degree wheel mounted on the rear of the spindle, and a way stop to limit the line length.

here I have done the ten degree marks. Next I will do the 5 degree marks , and then the 1 degree marks.

here I have done the ten degree marks. Next I will do the 5 degree marks , and then the 1 degree marks.

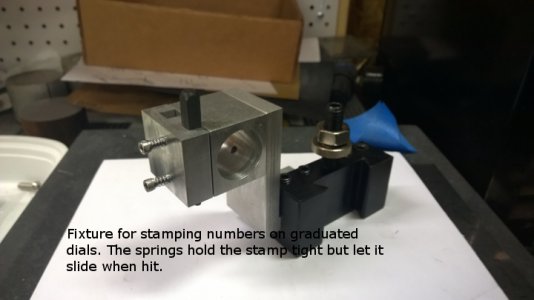

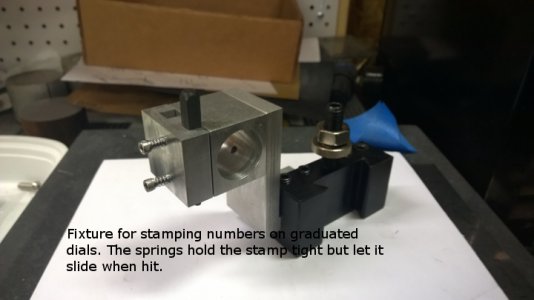

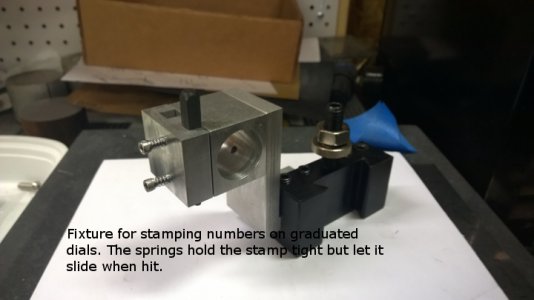

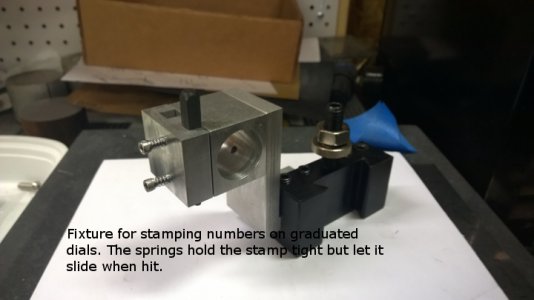

After marking all the degree marks, I had to stop and make a fixture to hold my number stamps so I could stamp the degree numbers with some sort of accuracy. So this is what I made for that purpose.

After marking all the degree marks, I had to stop and make a fixture to hold my number stamps so I could stamp the degree numbers with some sort of accuracy. So this is what I made for that purpose.

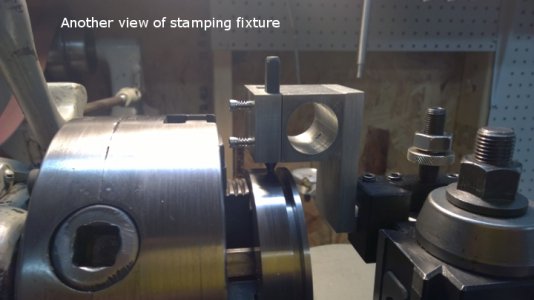

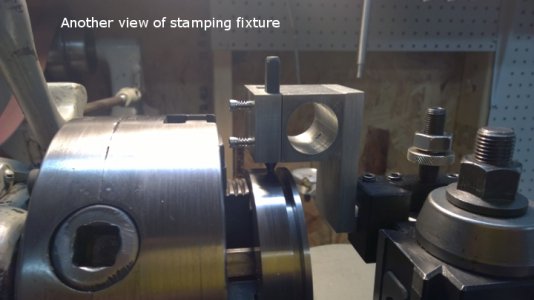

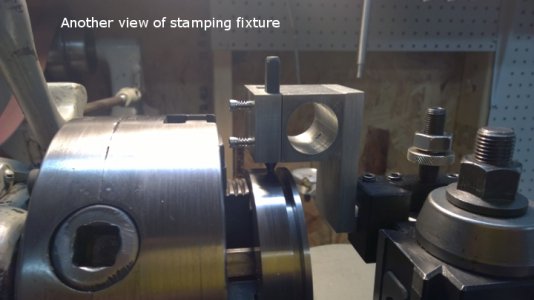

This view shows how it works. There is a thread about this fixture in "what you did in the shop today"

This view shows how it works. There is a thread about this fixture in "what you did in the shop today"

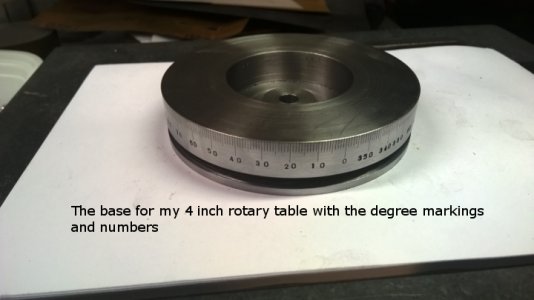

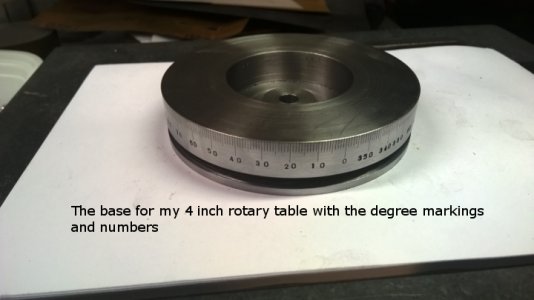

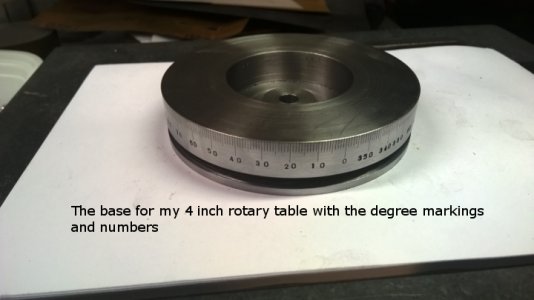

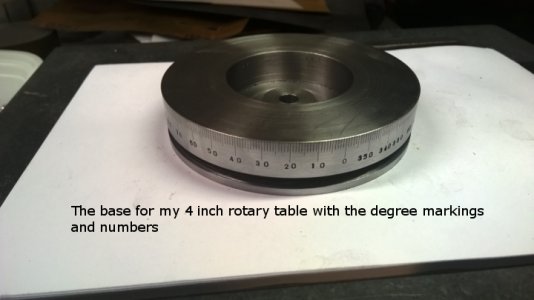

These three photos show the degree marks and the stamped numbers.

These three photos show the degree marks and the stamped numbers.

Stamping the numbers was a learning process. Not all are perfect, but they came out pretty good. now that I know how to do it the next ones I do will be much better.

Stamping the numbers was a learning process. Not all are perfect, but they came out pretty good. now that I know how to do it the next ones I do will be much better.

This is the finished base. As soon as the bearings arrive, I will make the rotating part. I still have to make some small clamps to hold it to the table. I will make those while waiting for the bearings.

This is the finished base. As soon as the bearings arrive, I will make the rotating part. I still have to make some small clamps to hold it to the table. I will make those while waiting for the bearings.

Keep watching,

Mark Frazier

After machining the round to 4 inches diameter, machining the bearing recess, and machining a clamping groove around the bottom, it was time to scribe the degree markings. This is the setup for making the lines. A boring bar with a pointed tool bit, my home made degree wheel mounted on the rear of the spindle, and a way stop to limit the line length.

After machining the round to 4 inches diameter, machining the bearing recess, and machining a clamping groove around the bottom, it was time to scribe the degree markings. This is the setup for making the lines. A boring bar with a pointed tool bit, my home made degree wheel mounted on the rear of the spindle, and a way stop to limit the line length. here I have done the ten degree marks. Next I will do the 5 degree marks , and then the 1 degree marks.

here I have done the ten degree marks. Next I will do the 5 degree marks , and then the 1 degree marks.  After marking all the degree marks, I had to stop and make a fixture to hold my number stamps so I could stamp the degree numbers with some sort of accuracy. So this is what I made for that purpose.

After marking all the degree marks, I had to stop and make a fixture to hold my number stamps so I could stamp the degree numbers with some sort of accuracy. So this is what I made for that purpose. This view shows how it works. There is a thread about this fixture in "what you did in the shop today"

This view shows how it works. There is a thread about this fixture in "what you did in the shop today" These three photos show the degree marks and the stamped numbers.

These three photos show the degree marks and the stamped numbers. Stamping the numbers was a learning process. Not all are perfect, but they came out pretty good. now that I know how to do it the next ones I do will be much better.

Stamping the numbers was a learning process. Not all are perfect, but they came out pretty good. now that I know how to do it the next ones I do will be much better. This is the finished base. As soon as the bearings arrive, I will make the rotating part. I still have to make some small clamps to hold it to the table. I will make those while waiting for the bearings.

This is the finished base. As soon as the bearings arrive, I will make the rotating part. I still have to make some small clamps to hold it to the table. I will make those while waiting for the bearings.Keep watching,

Mark Frazier