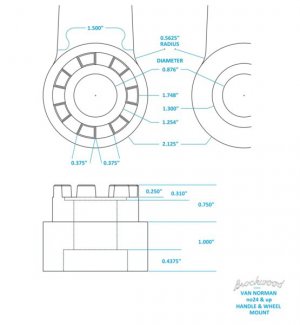

My Van Norman no24 is missing the X-axis hand crank wheel. Chris also has a Van Norman no24 that is missing a hand crank handle. We have been sharing info back & forth. I've put together our findings in picture format. It would be very beneficial if others with different models could compare their handles & wheels to these & let the group know if they are the same for a no12 or whatever model you have. In the midst of measuring up my handles, I found a no38 being parted out & was able to buy the hand crank wheel - hope it fits! 1st up is the wheel.

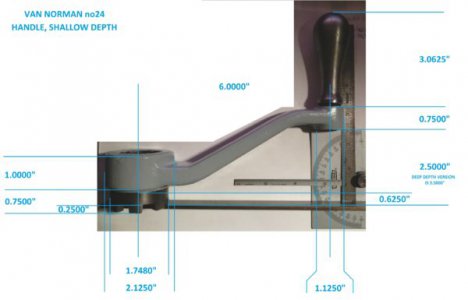

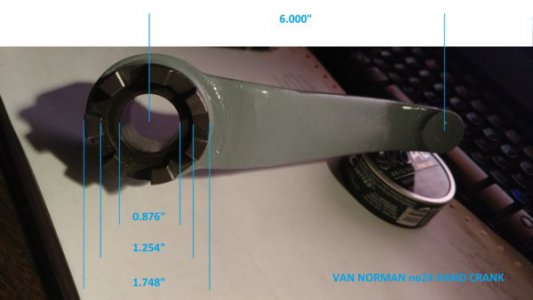

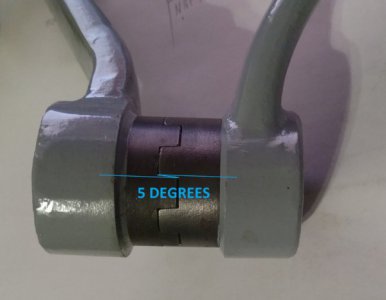

Next come the handles.

Next come the handles.

Last edited: