- Joined

- Sep 24, 2013

- Messages

- 397

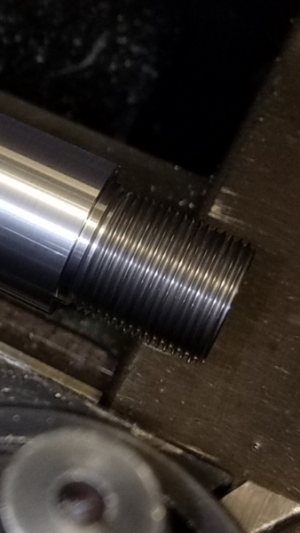

I just bought a Micro-100 internal threading tool. WOW! yes it's carbide but cut well at slower speeds and the finish was superb. I use carbide for most external threading,ie. barrel threads. I'm fond of the standup type. and gold or Al-ti coating.Tighten everything down and run the machine at the speed you feel comfortable with. Speed threading will come with practice. I have threaded some finer threads in direct drive. You just have to be able to kick out the half nut FAST. And make your clearance (one of them tolerance boys) as deep as the thread is then finished. Look on your fishtail. Mine have the actual depth on one and the feed in inches at 30 (29.5) degrees on the other. A real time saver. If it's English threads or for Mauser rifles it's 55 degrees. Then there is the really odd fishtail that is 90 degrees. For some goofy oilfield application. Just turn steel into little pieces and then learn to thread then together with almost no wiggle. Regular hardware nuts and bolts are a 75% thread which is almost as strong as a 99% thread but barrel threads need to be a lot closer to make it shoot well. Have fun!