-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hardening oven saga

- Thread starter Ferrous Turner

- Start date

The best thing you can do is salvage what you can and get some proper insulating fire bricks. They come in the same size albeit a bit thicker than the bricks you used so you should be able to reuse the frame you built. The bricks you used are not suited to the task and you will spend twice the price of the proper insulating bricks to build a kiln that will work half as well. Its sort of like trying to fix a cup of coffee after putting in a teaspoon of salt...

bob

bob

- Joined

- Apr 4, 2018

- Messages

- 53

I think you're right Bob. In fact, I was looking at those bricks on Ebay this morning and thinking the same thing. If I keep using what I have, I'll just be insulating a glowing Fukushima. It would take half a day to cool down enough to even open it.

Sigh..... I really liked that little oven the way it is.

Sigh..... I really liked that little oven the way it is.

- Joined

- Apr 4, 2018

- Messages

- 53

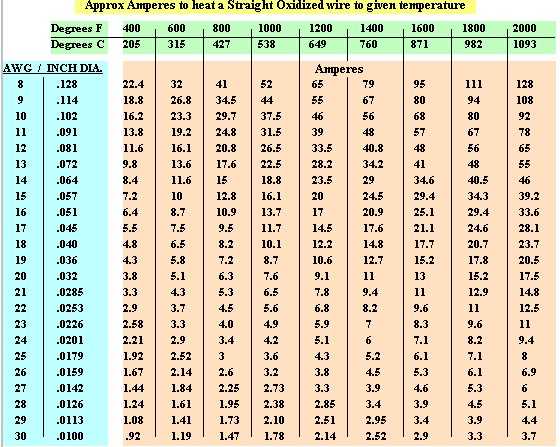

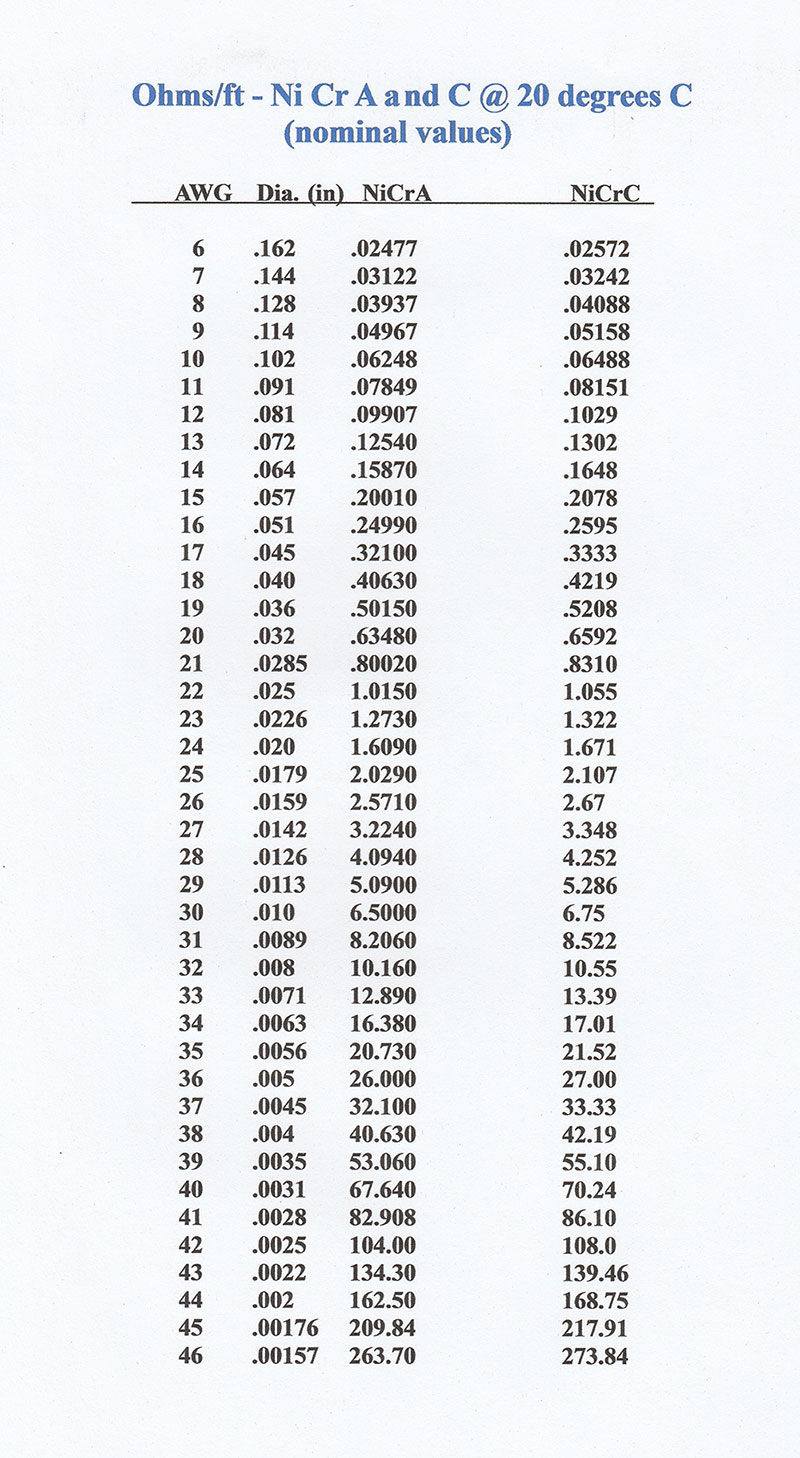

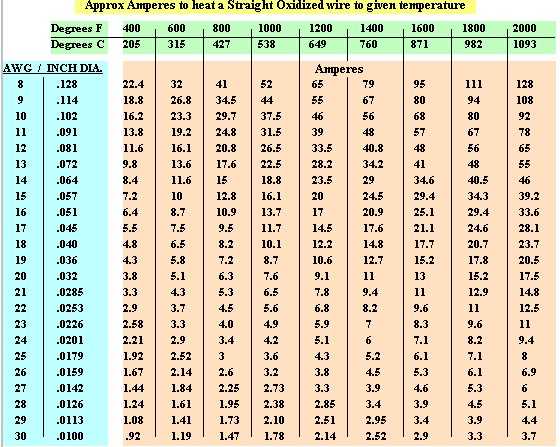

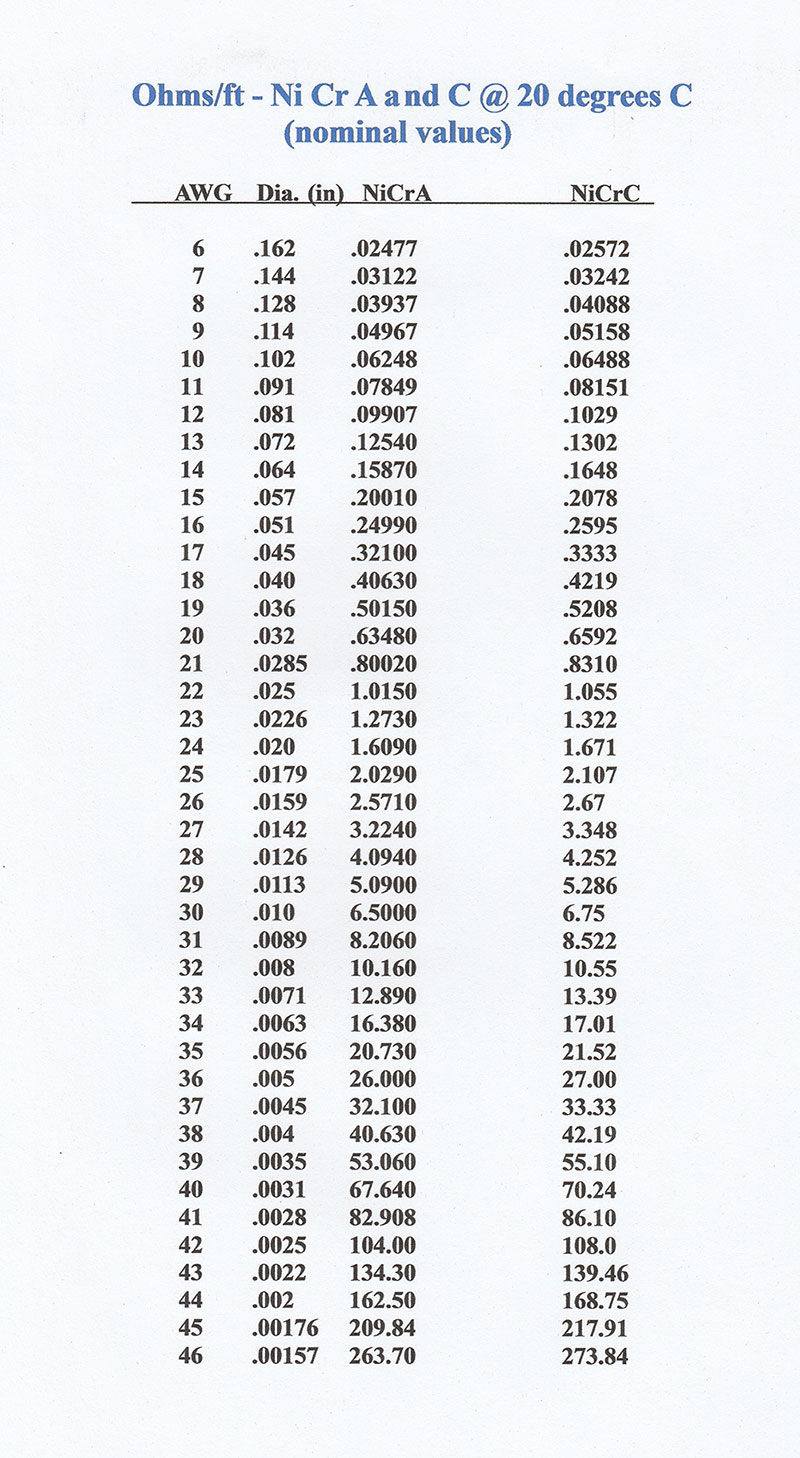

Some good info...

Current / Temperature Table – Ni Cr A (80) & Ni Cr C (60)

Current / Temperature Table – Ni Cr A (80) & Ni Cr C (60)

- Joined

- Apr 4, 2018

- Messages

- 53

OK, I bought new bricks and some 18 gauge nichrome wire. Should be here in about a week. In the meantime I'll demo the old oven (sniff...) and add a new 30 A outlet.

Ted

Ted

- Joined

- Apr 4, 2018

- Messages

- 53

Dang, the bricks arrived but they didn't survive shipping. 7 of the 12 I ordered suffered damage.

They were poorly packed, and no matter how many fragile stickers you put on a package it won't stop the gorillas from tossing the box during handling.

I filed a claim with the vendor, but this sets me back a week or two.

They were poorly packed, and no matter how many fragile stickers you put on a package it won't stop the gorillas from tossing the box during handling.

I filed a claim with the vendor, but this sets me back a week or two.

- Joined

- Apr 4, 2018

- Messages

- 53

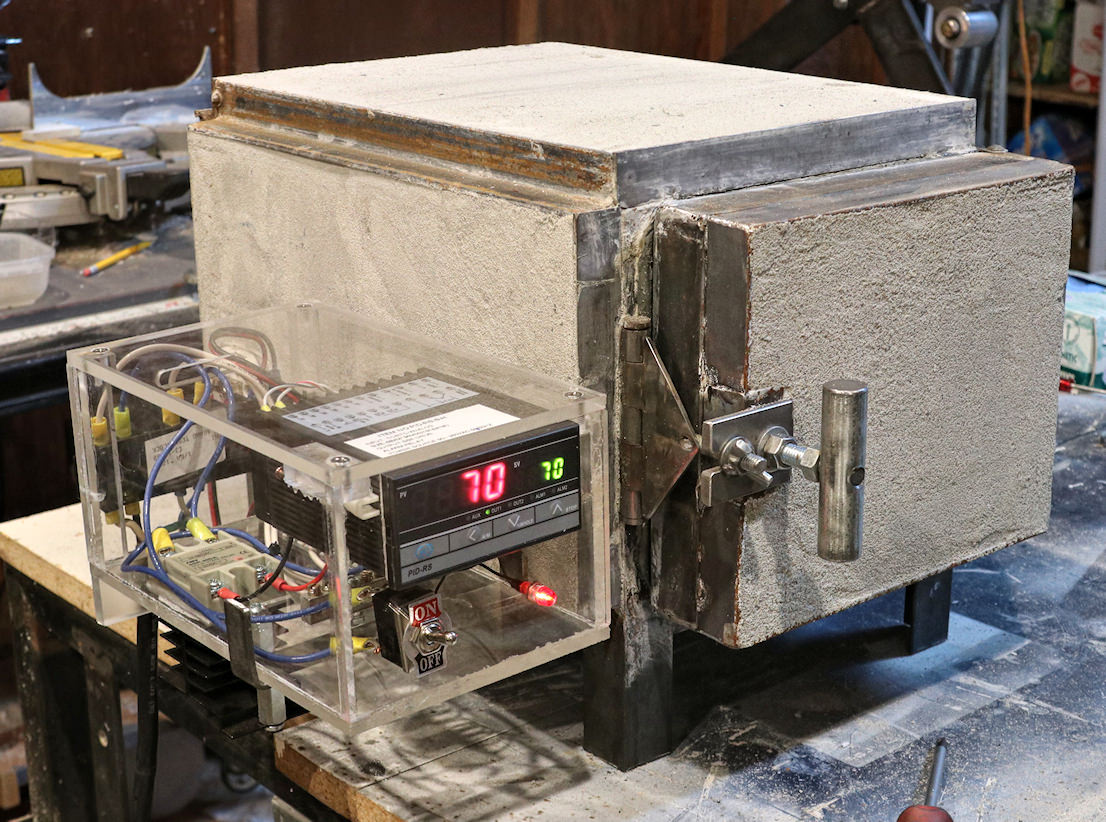

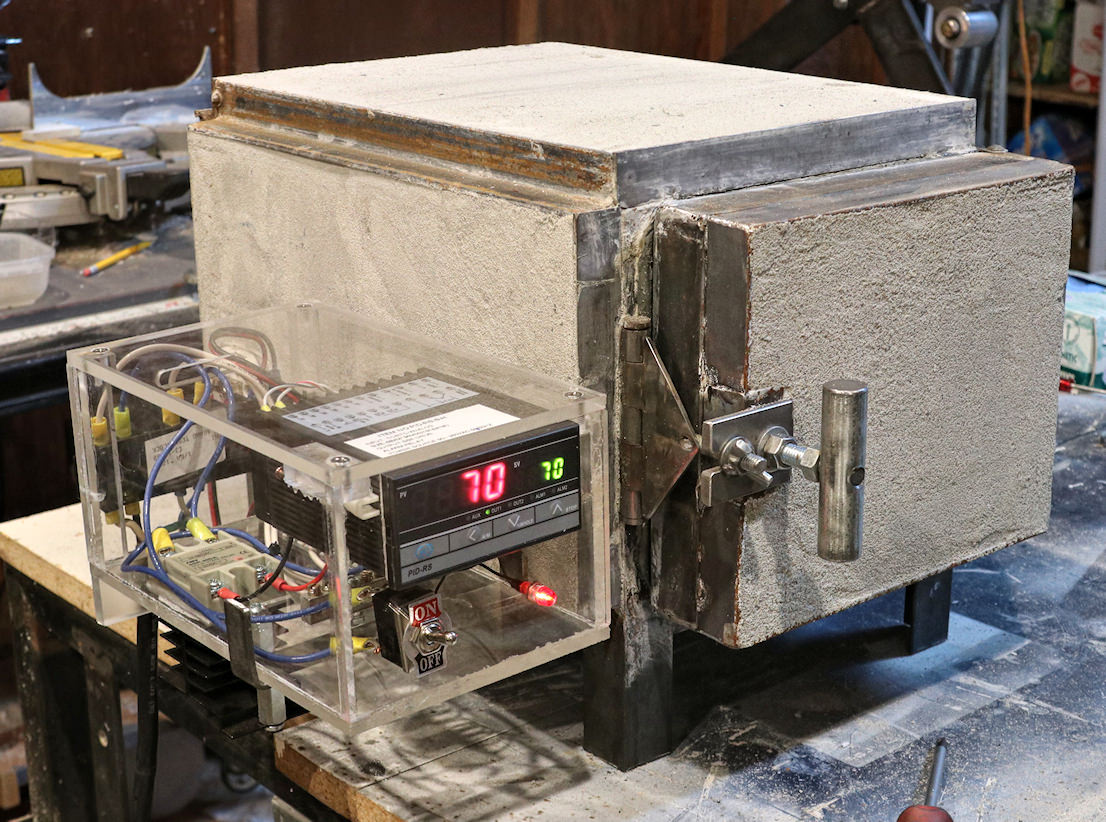

I was thinking... The first oven I built was actually constructed quite well. The only issue I had was thinking of it as an oven. It's really a forge.

All I have to do is add a propane burner and I have a forge. Good thing I didn't break it apart.

I'll be a blacksmith in no time!

All I have to do is add a propane burner and I have a forge. Good thing I didn't break it apart.

I'll be a blacksmith in no time!

- Joined

- Jan 2, 2014

- Messages

- 8,852

All I have to do is add a propane burner and I have a forge.

actually three great outcomes:

1) you now have a forge

2) you learned a bunch

3) you shared it and taught us some lessons

-brino

- Joined

- Apr 4, 2018

- Messages

- 53

I built a couple of burners to test things out. I had a burner that I used for my still, so I took the nozzle off that and used it for the forge.

I stacked some steel pipes together and put the nozzle on top in a simple arrangement.

I also had to cut a hole in the top of the forge to put it through. I drilled a bunch of holes with my hammer drill then knocked the plug out and cleaned up the sides with a cold chisel.

The burner worked, but the flame wasn't focused at all. It was also sputtering which I didn't like.

I built a second head which worked better than the first. It didn't sputter and the flame was more concentrated.

I stuck a piece of steel in there and waited about 20 minutes but it didn't even start to change color. I need a more focused and hotter flame.

I have a blower, which I pointed at the air holes. Now we're talking! Nice focused flame right on the steel.

I'm going to start building a forced air feed burner tomorrow. I also want to drill a couple of vents in the sides so I can close the door.

Ted

I stacked some steel pipes together and put the nozzle on top in a simple arrangement.

I also had to cut a hole in the top of the forge to put it through. I drilled a bunch of holes with my hammer drill then knocked the plug out and cleaned up the sides with a cold chisel.

The burner worked, but the flame wasn't focused at all. It was also sputtering which I didn't like.

I built a second head which worked better than the first. It didn't sputter and the flame was more concentrated.

I stuck a piece of steel in there and waited about 20 minutes but it didn't even start to change color. I need a more focused and hotter flame.

I have a blower, which I pointed at the air holes. Now we're talking! Nice focused flame right on the steel.

I'm going to start building a forced air feed burner tomorrow. I also want to drill a couple of vents in the sides so I can close the door.

Ted