- Joined

- Mar 26, 2018

- Messages

- 8,407

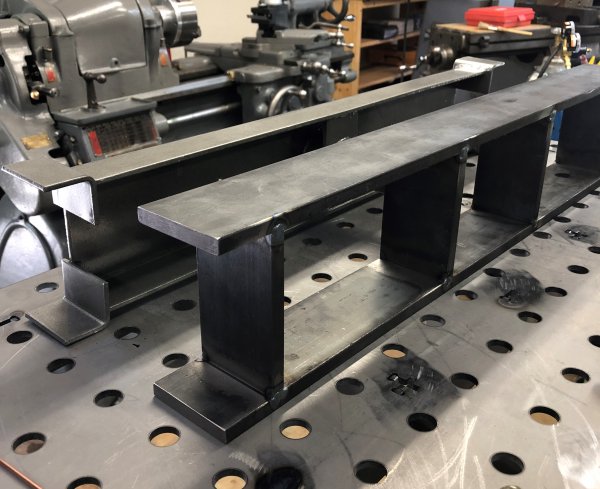

The first thing I noticed about this press is the lack of vertical stability. I welded on some triangular plates once squared.

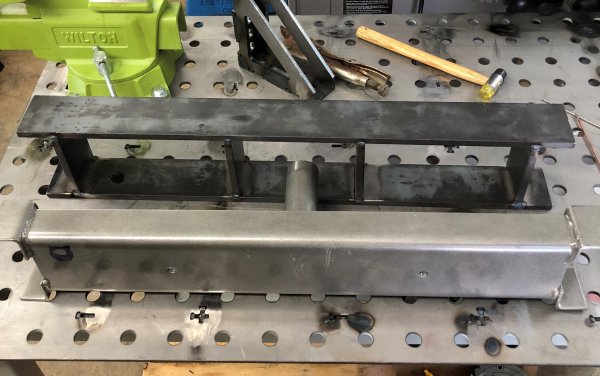

I am also replacing the press mounting plate. The one that it comes with is loose and tilts plus they used very thin metal.

I am going to weld on two plates with bored holes for the press shaft/pin. I plan on making different size adapters that can be installed/removed by a simple set screw.

Stay tuned.

I am also replacing the press mounting plate. The one that it comes with is loose and tilts plus they used very thin metal.

I am going to weld on two plates with bored holes for the press shaft/pin. I plan on making different size adapters that can be installed/removed by a simple set screw.

Stay tuned.