The additional start cap arrived and I pretty much wrapped up the project. Only a few minor details remain.

I mounted the start-stop switch next to the cabinet until I figure the best location. I could even have one by each machine.

I mounted the idler motor on a pair of hardwood skids and set it on a piece of rubber sound attenuation matting. I'll also make a cover for exposed shaft. I milled out the back of a 5" junction box and mounted it to the terminal box that was missing it's cover.

Next time I get in there, I'll shorten & neaten up the cap wires and make a retaining strap to keep them in place when opening the cabinet.

Eventually, I'll place the idler under the lathe, where there's plenty of dead space.

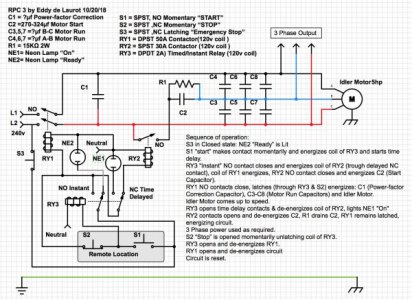

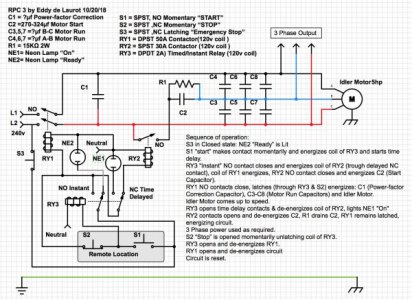

The final schematic, pretty much as built. I didn't mount S3 (E-stop) for now as the Start-Stop switch is right next to the cabinet.

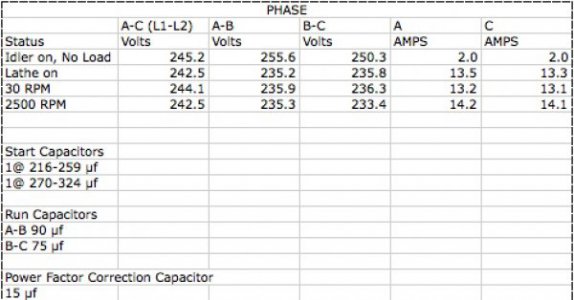

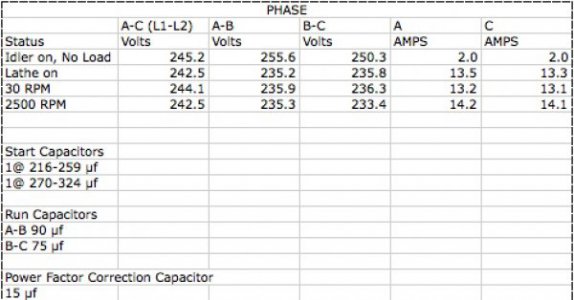

This is how it balanced out, I'm very happy with the results. I wasn't able to measure the current on phase B (the generated phase) as I couldn't pull out enough wire to get the ammeter on it, perhaps next time... But it probably isn't necessary as the system runs smooth and quiet, which is what I was after.

Now it's back to Craigslist with the George Snyder unit...