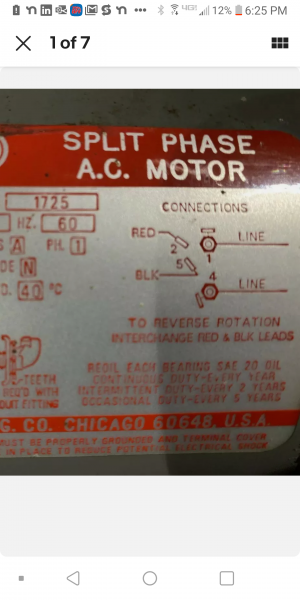

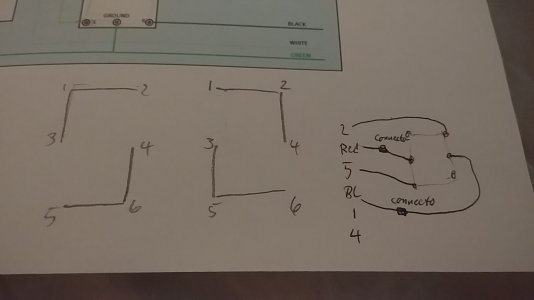

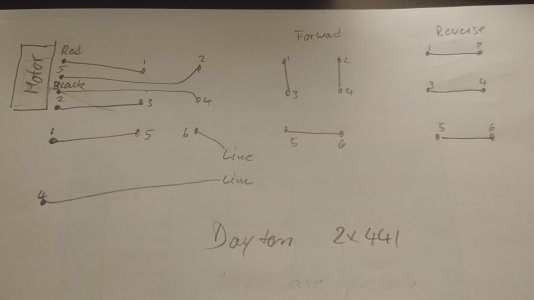

Awright, lets get a little more basic here. The photo of the motor shows two studs. Those are the line leads. Connect (L)Black to one, (L)White to the other. The motor should run. Direction is not important here. Now remove the (L)Black lead from the stud. In its' place connect one of the runners to the switch. Then connect another runner to the (L)Black lead from the line cord. When these two runners are tied together, the motor will run. Assuming the cord is plugged in first, of course.(humor intentional) Those are the two wires to connect to (S)5 and (S)6.

Proving the motor isn't that important. It's new, it most likely works OK. Where this "exercise" does matter is proving the wiring as you put it in. That, and taking things one step at a time. And paying attention to what you're doing as you do it. That's why I brought up the universal lubricant. It makes this part go so much smoother. A most important part of doing any electrical work. I have had this deformation since 1968. A semi-permanant deformation of the starboard thumb and fore-finger. Known more colloquially as "Petty Officer Fingers". It almost resembles rhumotoid arthritus, having the same deformation, but limited to those two digits. Now, I used a few "abreviations" that may or may not be standards. I'm getting old and the memory doesn't work as well as it once did. FWIW, the "Avatar" picture is over 10 years old. What was once salt and pepper is now salt.

(L)Black and like is the line cord

(M)Black and like is the motor

(S)1 and like is the switch

EDIT: Or call it an afterthought... ... There are many ways to make up this connection. I have explaned it the way I do it. The line cable coming in to the motor. It may also come into the switch. But drum switches are rather close. There is not a lot of excess room inside. Bringing the line cord into the motor usually has a little more space to make up. Using the proper "lugs" on the wires does help some. Just make sure wires don't touch.

As an aside, if needed, I purchase AWG14 extension cords, usually 10 foot, occasionally 25. Cut off the female cap and get your line cord. Be sure not to get the cheaper cords, AWG-16 or smaller. Cut the cap with long leads so you can splice it on to something if you ever need it. Rare though, I have a box full of cutoffs "Just In Case". Also, I want to "rant" just a little. Only take a few lines.

All readers, please note. Electrician and Electronics are NOT the same. I am mildly qualified in electronics, but not a master by any stretch. And then both are further divided into many different disciplines. My brother was a master LORAN mechanic. I am an electrical engineer. We can barely understand each other in a technical conversation. About the only common ground is "Basic Electrical Theory". If you touch a "hot" wire, you get zapped. Another way to put it, is that I speak three languages: English, Electricity, and Computers. Brother also speaks three languages: English, Electronics, and Radio.