- Joined

- Nov 15, 2016

- Messages

- 943

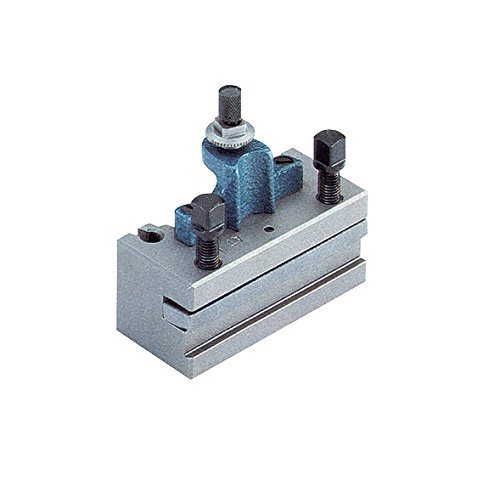

I still wonder ...can you just use a parting tool holder and turn the blade upside down?

As long as you can get the tip on center then no problem. As noted by several people if a relief clearance is needed with HSS or a cast blade like a Crobalt then again no problem as long as it is the right way up/down.

My opinion for the little it is worth is that running the blade with the cutting edge at the bottom has so many advantages I try to do this as often as possible. Threading away from the chuck is so safe it is my preferred method. Even plain turning particularly with something like Brass I like all the chips going down. Once you get used to it it is like everything else you will swop back and forth depending on the work. The only kicker being to always remember which way to push the control lever.