- Joined

- Aug 26, 2014

- Messages

- 132

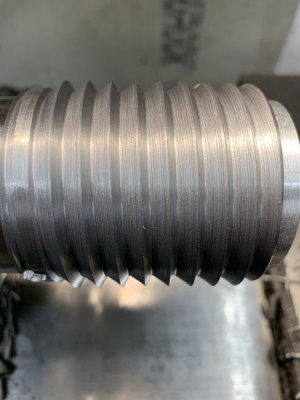

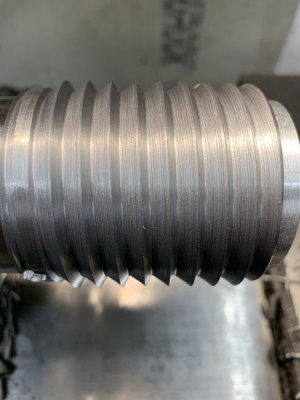

I was cutting this 4 tpi thread. I set the cross slide to zero, and "closed" the compound to it's furthest location (where I usually keep it when I'm not using it) and zeroed it, then I touched onto the area of the work at the depth where the root width was appropriate, re-zeroed the dial, removed the tool from the work, and advanced the cross slide to the full depth of thread. Then I reset THAT to my Zero location. Then I pulled the compound off until the tool would just barely touch the work, and began threading with the compound only, retracting the tool from the compound as needed to clear the thread priorly cut; I repeated this until I was close to where I thought I should be. Here's the problem:

I don't know. Somewhere along the line, I thought the right flank of the thread was looking a little shallow, and I noticed that my HSS cutting tool (which I ground like a CHAMP, might I add) had nudged just a tad off to one side. Maybe 3º. I tapped it into place, and found the lost thread, resetting the dials to the numbers where I was when I noticed the problem. Well, the thread doesn't look right to me, and I was hoping someone could set me straight, or tell me to do it again.

Maybe I should just keep going in with the compound?

This is a hugely complicated part to do, and if I don't have to, I don't want to have to start over from scratch.

I've never cut a 4 TPI thread before, and I've never fed from the compound before, so I'm a bit out of my element here. Please have a look at this for me and tell me if you think this is right.

I don't know. Somewhere along the line, I thought the right flank of the thread was looking a little shallow, and I noticed that my HSS cutting tool (which I ground like a CHAMP, might I add) had nudged just a tad off to one side. Maybe 3º. I tapped it into place, and found the lost thread, resetting the dials to the numbers where I was when I noticed the problem. Well, the thread doesn't look right to me, and I was hoping someone could set me straight, or tell me to do it again.

Maybe I should just keep going in with the compound?

This is a hugely complicated part to do, and if I don't have to, I don't want to have to start over from scratch.

I've never cut a 4 TPI thread before, and I've never fed from the compound before, so I'm a bit out of my element here. Please have a look at this for me and tell me if you think this is right.