- Joined

- Mar 26, 2018

- Messages

- 8,388

I changed the oil for the head stock reservoir yesterday. Wow, it took 4.7. gallons.

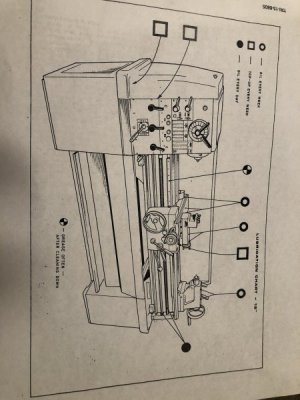

This lathe is very similar to the Triumph 2000 and the 1500.

The way they designed and manufactured this lathe is incredible, at least IMHO.

The gear box oil is getting changed today.

There doesn’t seem to be many In this group that own one of these.

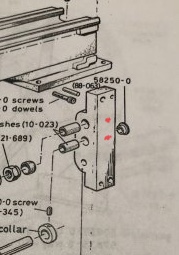

When I see videos on the start up, the sight glass for the headstock oil fills with oil showing good flow.

On mine, you can see the oil flow but the glass does not fill.

I noticed when I drained the oil, it looked thicker than the oil I put in. (Yes, I used the correct oil)

When I had it powered up when I bought it, I took the cover off and watched the oil lubricate properly.

I can’t power it up yet, I’m hoping the new lubricant will match the character of the videos I have seen.

I wouldn’t know where to begin to diagnose low flow. It’s a simple belt driven impeller type pump.

Anyone experience this? Do you think it could be the viscosity?

This lathe is very similar to the Triumph 2000 and the 1500.

The way they designed and manufactured this lathe is incredible, at least IMHO.

The gear box oil is getting changed today.

There doesn’t seem to be many In this group that own one of these.

When I see videos on the start up, the sight glass for the headstock oil fills with oil showing good flow.

On mine, you can see the oil flow but the glass does not fill.

I noticed when I drained the oil, it looked thicker than the oil I put in. (Yes, I used the correct oil)

When I had it powered up when I bought it, I took the cover off and watched the oil lubricate properly.

I can’t power it up yet, I’m hoping the new lubricant will match the character of the videos I have seen.

I wouldn’t know where to begin to diagnose low flow. It’s a simple belt driven impeller type pump.

Anyone experience this? Do you think it could be the viscosity?