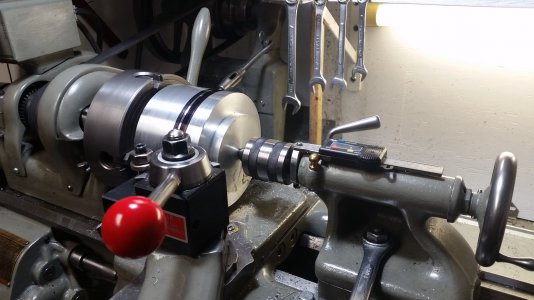

I repaired a beam trolley where one wheel had a missing chunk. TIG brazed Al bronze and machined back. The rolling surface was nonconcentric with the bearing by about 0.1” so I’m machining each of the rollers at least close to concentric. They are really tough steel and it’s brutal on the tool.