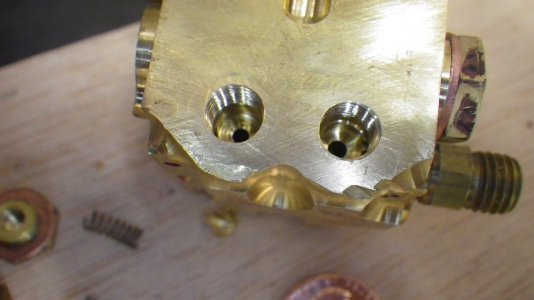

well after some time away started back on this project,, with some tap and die work, a little bit of silver soldering, some quick mill work,, the 8 threaded valve caps for the pump end were made.. they still need a little work and some sealing washers need to made.. slim is back at work inspecting and being judgmental...

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/6th scale 1890's 30ft navy steam cutter (live steam)

- Thread starter tghsmith

- Start date

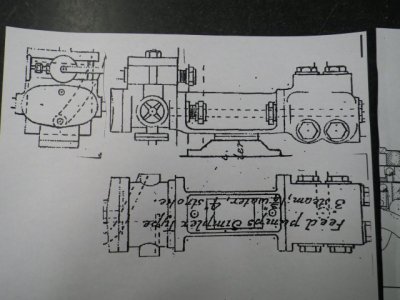

started working on the valve internals, turned 2 types, thinking the ball holder type will be the way to go,, quick work using a 1/8"th ball mill.. 7 more and a few spares to turn.. made some gear for slim so he can take on groat (the shop floor monster)

Attachments

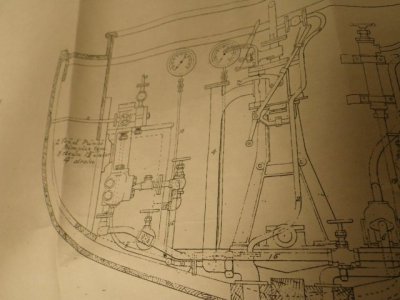

some project updates,, not much work on the little pump.. started fitting and finishing the hull fittings that were made a while back,, these have to be done before hull construction can start,, cut-water had bullnose parts added plus a correct hull number added and the mounting sleeve bolts were made,, stern parts were shaped a bit and mounted to the stern wood section,, a prop shaft tube was made along with a thrust box,, bell ended to use a bigger bearing on the prop end,, the entire assembly spins nicely on the shaft.. the hoisting fittings were rounded and mounting clamps were made.. should be able to start the hull work soon..

Attachments

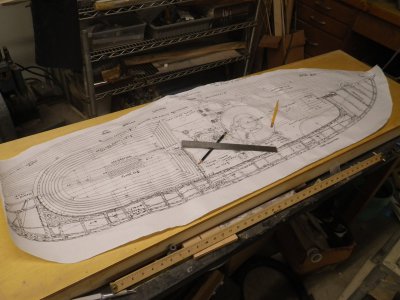

not much metal work for a bit, but this kiln dried oak is pretty close,, the keel is all together,, profile plan removed and getting ready to set the overhead plan to the building board..