-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

11.5 tpi

- Thread starter neilking

- Start date

- Joined

- Jul 2, 2014

- Messages

- 7,594

You will need to tell us more to get a useful answer. What lathe? Metric or Imperial lead screws? Do you have the correct change gears (if needed) to do 11.5 tpi? Will the 11.5 thread be straight or tapered? What are you making?

Edit: Answering the following questions might also help your project. Will the thread be required to seal against gaseous or liquid pressure without leaking? If so, how much pressure?

My Kent USA 13x40 with a 8 TPI lead screw, 4" per revolution threading dial, and 32 tooth threading dial gear can be used for 11.5 TPI if always engaged on the same number.

Edit: Answering the following questions might also help your project. Will the thread be required to seal against gaseous or liquid pressure without leaking? If so, how much pressure?

My Kent USA 13x40 with a 8 TPI lead screw, 4" per revolution threading dial, and 32 tooth threading dial gear can be used for 11.5 TPI if always engaged on the same number.

Last edited:

- Joined

- Dec 31, 2010

- Messages

- 937

If you have a 11.5 square on your quick change on your lead screw gear box Yes. I am sure the machinists that change the gearing on the end of their lathes will have some interesting comments on this. I say yes with out going out to the shop to check the threading chart on the Clausing but I am reasonably sure it has an 11.5 setting. I re-read your question thus the following comment I would use the same number on the threading dial for each pass. Are you cutting internal or external threads? Maybe both so enjoy. Please excuse the jump to conclusions at the beginning of this response.

Have a good day

Ray

Have a good day

Ray

- Joined

- Feb 1, 2015

- Messages

- 9,574

My Grizzly G0602 will cut an 11.5 tpi thread. The thread dial will work with any two marks diametrically opposite each other (1 & 7, 2 & 8, 3 & 9, 4

&10, 5 & 11, or 6 & 12).

&10, 5 & 11, or 6 & 12).

- Joined

- Jun 7, 2013

- Messages

- 10,071

Can't say for others, but my 19" Regal will cut 11-1/2 TPI, and will engage properly on opposite numbers on the thread dial; only if there are quarter threads, do I have to engage on the same number; this applies to any lathe with a 4 TPI lead screw.

Last edited:

- Joined

- Aug 29, 2013

- Messages

- 1,050

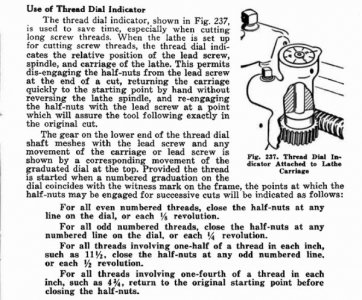

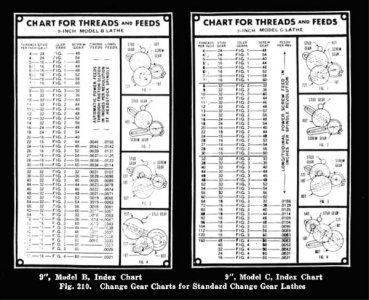

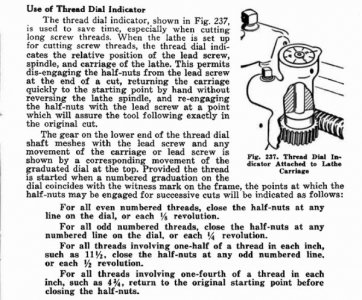

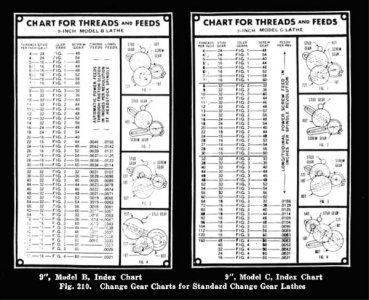

The instructions for the SB 9B are in "How To Run a Lathe".

http://www.campkahler.com/files/How_to_Run_a_Lathe_SB_1of2.pdf

http://www.campkahler.com/files/How_to_Run_a_Lathe_SB_2of2.pdf

Excerpts:

http://www.campkahler.com/files/How_to_Run_a_Lathe_SB_1of2.pdf

http://www.campkahler.com/files/How_to_Run_a_Lathe_SB_2of2.pdf

Excerpts: