-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1144 Stressproof

- Thread starter ddickey

- Start date

4

4GSR

Forum Guest

Register Today

SWEET!!!

Nice stuff to cut on if you need that extra strength out of it. It is also offered in Turned, Ground and Polished, too.

I keep a few pieces on hand just for that special project. Speedy Metals is where I buy my stuff from. Ken

Nice stuff to cut on if you need that extra strength out of it. It is also offered in Turned, Ground and Polished, too.

I keep a few pieces on hand just for that special project. Speedy Metals is where I buy my stuff from. Ken

Last edited by a moderator:

- Joined

- Dec 20, 2012

- Messages

- 9,422

Not sure what DDickey is using but I rough at 60 SFM and finish with light cuts at my lathe's max speed. My side and end relief angles are 15 degrees, side rake 22 degrees and back rake 18 degrees. Nose radius is 1/64". Rough slow, finish fast, sulfur-based cutting oil. The trick with 1144 is to get the heat out of the cut fast, which is why the rake angles are what they are.

1144 has to be rigidly held; it won't cut clean between centers but when held in a 3 jaw on one end and a good live center it will cut nicely with the above tool.

1144 has to be rigidly held; it won't cut clean between centers but when held in a 3 jaw on one end and a good live center it will cut nicely with the above tool.

I turned at ~375 RPM with .0025/rev feed rate for roughing. Sped it up (750 rpm) for final cuts with a .00012/rev feed rate. I use a water soluble oil which really absorbs heat well so no problems there. Used an Arthur Warner HSS insert. 11 +degree relief angle and also a 1/16" radius. Maybe I'll try less radius like Mike next time.

Not sure what DDickey is using but I rough at 60 SFM and finish with light cuts at my lathe's max speed. My side and end relief angles are 15 degrees, side rake 22 degrees and back rake 18 degrees. Nose radius is 1/64". Rough slow, finish fast, sulfur-based cutting oil. The trick with 1144 is to get the heat out of the cut fast, which is why the rake angles are what they are.

1144 has to be rigidly held; it won't cut clean between centers but when held in a 3 jaw on one end and a good live center it will cut nicely with the above tool.

That's a lot of rake! Ok will try it again. What are the benefits of 1144 versus a more conventional steel like 1215 for ordinary parts?

- Joined

- Dec 20, 2012

- Messages

- 9,422

Not really a lot. Standard relief angles for machine steel is 10-12, side rake is 12-18, and back rake is 8-15. My changes are just slightly more relief to reduce cutting forces and the increased side and back rake reduce forces and improve chip clearance ... a lot. I make up for the increased angles with a smaller nose radius for strength. This tool cuts easily - I can rough 1144 at 0.100" cuts (0.200" off the diameter) without work hardening the surface, then come back with a 0.003" finish cut and hold tolerances without problems.

If you just need steel for a project, 12L14 or 1215 will do fine. If you need increased hardness or tensile strength then 1144 is a good choice. I like it for tool post studs or when a post is in tension. Nah, I'll be honest and say that I probably use it inappropriately because I actually like this stuff. It has a nice satin finish that appeals to my eye.

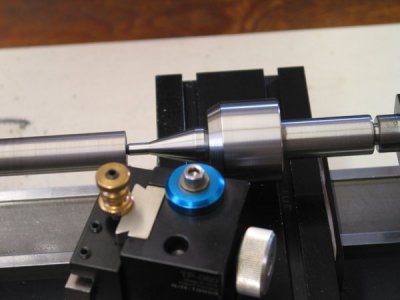

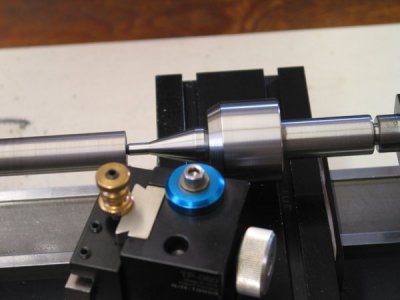

This is a live center for my Sherline lathe. The body and arbor are 1144, the tip is O-1 tool steel. All pieces are "as turned" on my lathe - no sanding or polishing on any of them. All pieces were turned on my Sherline lathe. I suppose I can improve on the finish a bit more if I sanded it but I sort of like the way it looks.

Forgot to add, that's another piece of 1144 chucked up in the lathe.

If you just need steel for a project, 12L14 or 1215 will do fine. If you need increased hardness or tensile strength then 1144 is a good choice. I like it for tool post studs or when a post is in tension. Nah, I'll be honest and say that I probably use it inappropriately because I actually like this stuff. It has a nice satin finish that appeals to my eye.

This is a live center for my Sherline lathe. The body and arbor are 1144, the tip is O-1 tool steel. All pieces are "as turned" on my lathe - no sanding or polishing on any of them. All pieces were turned on my Sherline lathe. I suppose I can improve on the finish a bit more if I sanded it but I sort of like the way it looks.

Forgot to add, that's another piece of 1144 chucked up in the lathe.

Last edited:

- Joined

- Feb 13, 2015

- Messages

- 5

... (750 rpm) for final cuts with a .00012/rev feed rate. ...

That's gotta' be a typo. 750 rpm x .00012 = .09 inches per minute!