- Joined

- Dec 29, 2013

- Messages

- 7

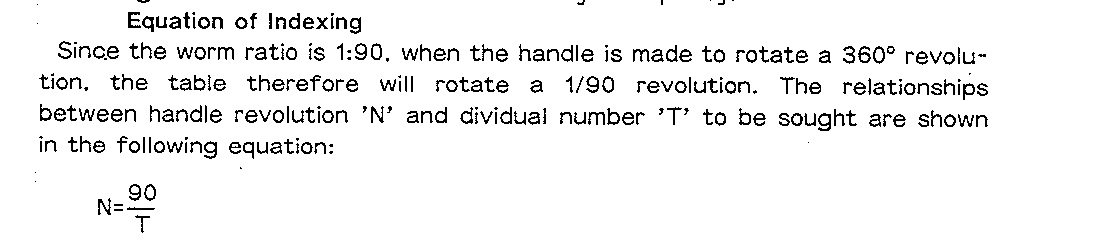

Hi, i'm new to this forum. I want to know if I build a 127 hole plate for my B&S BS0 dividing head if I will end up with 127 teeth on a gear? I need to make a 127 tooth gear for my Birmingham lathe so I can cut Diametral pitch and Module pitch worms. I will have to cut other gears also, but this is the only one I'm currently having trouble with. By my math if I rotate the plate 40 holes and make a cut and then rotate another 40 holes, when I get to the end I will have 127 teeth. Is this right? Thanks for any information or experience you have in this matter. Cuebuilder