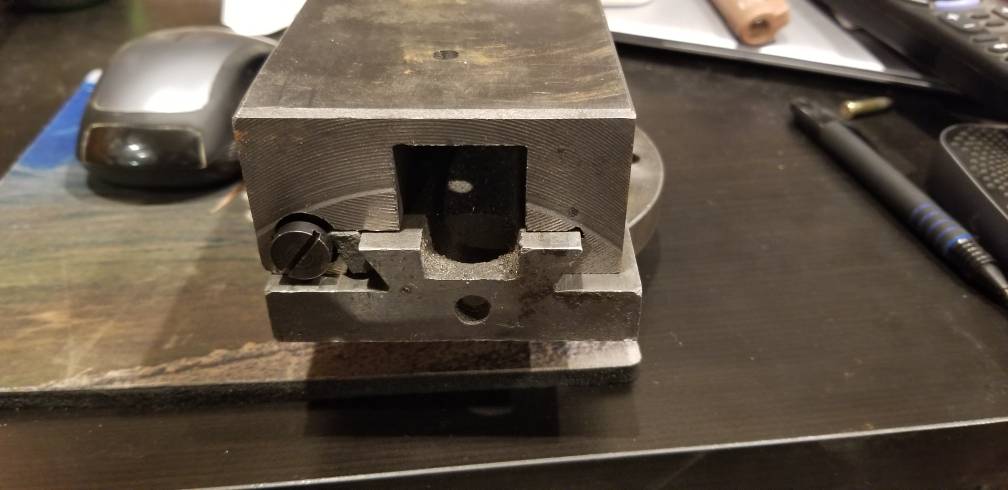

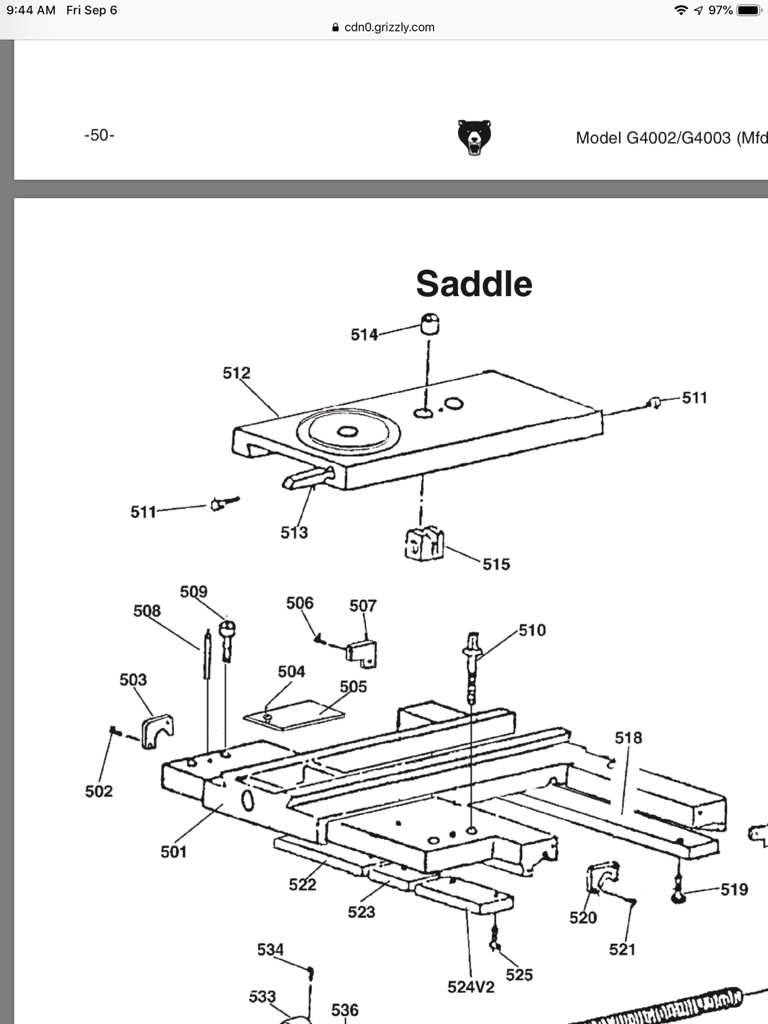

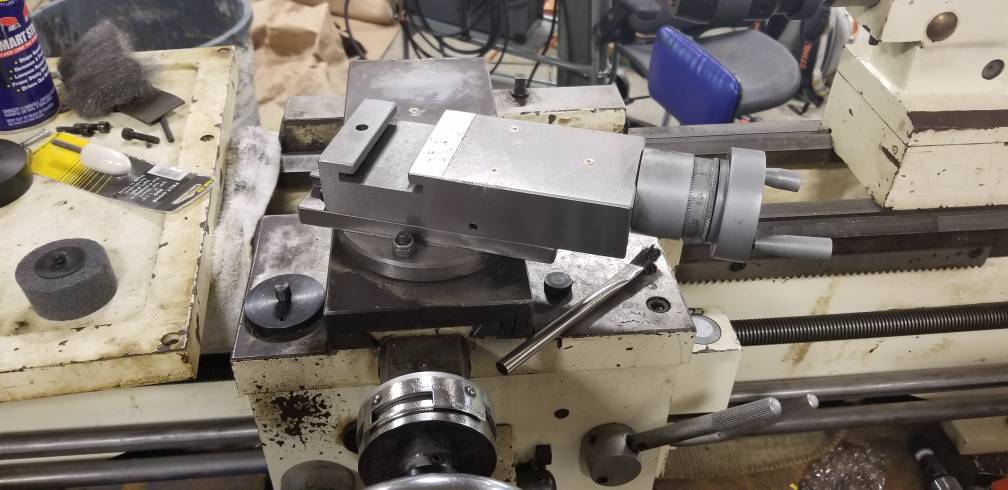

If anyone happens to have the compound off their g4003 and can compare these are the measurements I'm trying to validate.

Outer ring max dia to outside edge of mounting slot is 4.17" (105.5mm) inside edge is 3.39" (86mm) dia. Slot is .38" (10mm) wide. And the inside hole is 1.57" (40mm).

Sent from my SM-N950U using Tapatalk

Outer ring max dia to outside edge of mounting slot is 4.17" (105.5mm) inside edge is 3.39" (86mm) dia. Slot is .38" (10mm) wide. And the inside hole is 1.57" (40mm).

Sent from my SM-N950U using Tapatalk