- Joined

- Dec 3, 2017

- Messages

- 1,909

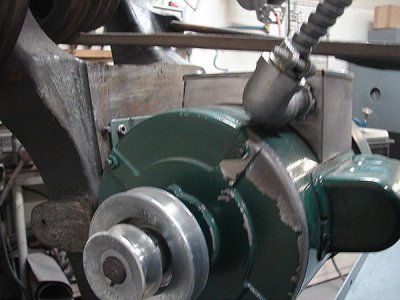

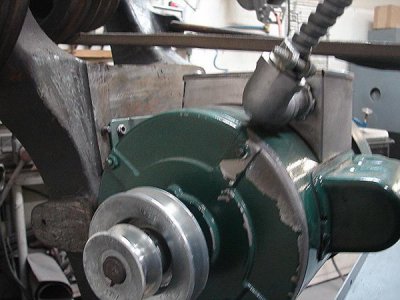

Ah ok I see it. You guys have good eyes! I didn’t pay much attention to that one, because I’d thought he said he was trying to reverse the green motor. Anyhow I see it now. Thank you.

Ok, so as I understand the dilemma, you have two different motors, and haven’t been able to reverse either one. There’s a suggestion to take the motor apart in order to get it to reverse, but I think that would only solve the issue if you wanted to permanently reverse rotation. Which is not the goal, if I’m understanding correctly. So, if I’m not totally lost here, which is quite possible, I will stand by my first post suggesting you find a motor with the obvious and blatantly printed ability to reverse on its motor data plate. Now having said that, I will check the motor that came with my Atlas lathe, which is reversible by magic that happens in the drum switch, and make sure it has the information I assume would be there. Lol Best regards to all!

As an aside, we have a machine at work that has 120 volt reversible motors on it, and that capability is printed on the motor. However anecdotal that nugget may be. And you do have to get inside the motor connections box to change it, but there are extra leads, and it could be wired to a drum switch if you wanted the option of either rotation at any time.

Ok, so as I understand the dilemma, you have two different motors, and haven’t been able to reverse either one. There’s a suggestion to take the motor apart in order to get it to reverse, but I think that would only solve the issue if you wanted to permanently reverse rotation. Which is not the goal, if I’m understanding correctly. So, if I’m not totally lost here, which is quite possible, I will stand by my first post suggesting you find a motor with the obvious and blatantly printed ability to reverse on its motor data plate. Now having said that, I will check the motor that came with my Atlas lathe, which is reversible by magic that happens in the drum switch, and make sure it has the information I assume would be there. Lol Best regards to all!

As an aside, we have a machine at work that has 120 volt reversible motors on it, and that capability is printed on the motor. However anecdotal that nugget may be. And you do have to get inside the motor connections box to change it, but there are extra leads, and it could be wired to a drum switch if you wanted the option of either rotation at any time.