- Joined

- Feb 25, 2021

- Messages

- 3,115

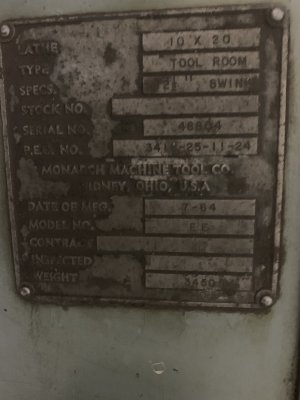

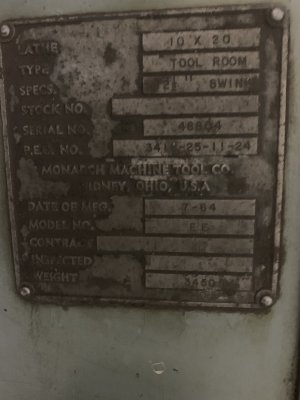

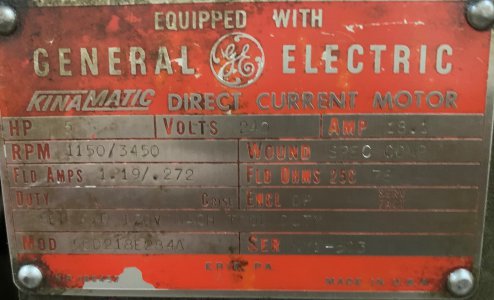

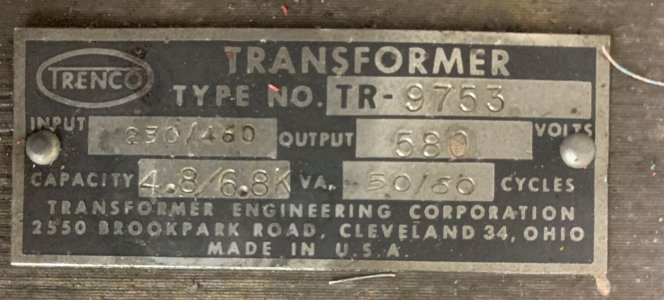

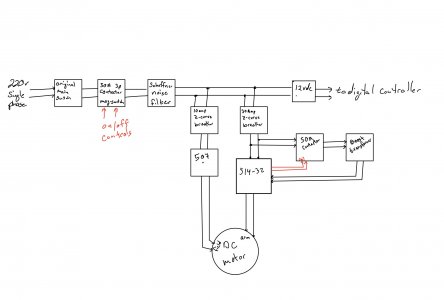

The CK I posted about in another thread is a great lathe, certainly sturdy. But it is not the machine for spinning anything over 1000rpm. I'd been working with a 10x22 import lathe and realized a spindle speed faster than 1000 is certainly useful for carbide on small diameters. And I decided I really like fixing up the older machines. About a year ago I ran across a Monarch 10EE for sale in Wisconsin. Pretty rough shape, but running. 5HP DC motor, that had been modified with an after market "Danfuss" controller that wouldn't run the spindle up over 1000rpm.

DC motors are a bit strange in that there is both an armature and field, basically a rotating electromagnet and a fixed electromagnet. The rotating electromagnet (armature) gets driven through brushes that activate the appropriate orientation to push against the fixed magnet (field). To vary speed in this type of DC motor the voltage to the armature is increased from zero to maximum, and then to go faster, the current to the field is decreased. (Sorry to any power/motor experts if I'm butchering this). That requires a fairly complicated set of controls feeding the DC motor. Monarch went through quite a bit of variation in doing this over the 4+ decades that the 10EE was mass-produced, and the control electronics have always been the Achilles heel of these lathes.

Anyhow, this lathe was meant to spin up to 4000rpm on the spindle, but the existing controller would only get up to about 1000 rpm.

I'll add more to this thread soon ...

DC motors are a bit strange in that there is both an armature and field, basically a rotating electromagnet and a fixed electromagnet. The rotating electromagnet (armature) gets driven through brushes that activate the appropriate orientation to push against the fixed magnet (field). To vary speed in this type of DC motor the voltage to the armature is increased from zero to maximum, and then to go faster, the current to the field is decreased. (Sorry to any power/motor experts if I'm butchering this). That requires a fairly complicated set of controls feeding the DC motor. Monarch went through quite a bit of variation in doing this over the 4+ decades that the 10EE was mass-produced, and the control electronics have always been the Achilles heel of these lathes.

Anyhow, this lathe was meant to spin up to 4000rpm on the spindle, but the existing controller would only get up to about 1000 rpm.

I'll add more to this thread soon ...

![IMG_3416[1].JPG IMG_3416[1].JPG](https://www.hobby-machinist.com/data/attachments/314/314860-657e118d48898fba6f1e4ae8d065b132.jpg)

![IMG_3421[1].JPG IMG_3421[1].JPG](https://www.hobby-machinist.com/data/attachments/314/314859-903c0c0ce9309f5f688491febf9f3961.jpg)

![IMG_3428[1].JPG IMG_3428[1].JPG](https://www.hobby-machinist.com/data/attachments/314/314861-0f4a64903fd6ccd66312e14c9159f2af.jpg)