- Joined

- Sep 26, 2013

- Messages

- 408

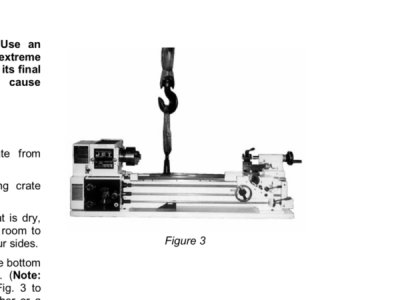

I have an Atlas 12x36, this came up about 100 miles from me and wondering what your collective thinking is on this deal, here's pics:

It was the sellers father in law who as a retired machinist bought this for home use(probably not the original owner). The seller does not know anything about lathes, it in his mom's garage and she wants it gone. Condition in the pics looks pretty good but hard to tell, accessories and tooling are a question but everything on the bench is included. Correct me if I'm mistaken but I believe this Taiwan made early 80s(?) Jet has hardened ways and is substantially heavier than the Atlas, and has a !.5" spindle(almost 2x the Atlas). Any weirdness associated with this era/model of Jet? Not sure what the PS means, I googled it but didn't find anything specific regarding it. They're only asking $500 for it, so I almost feel obligated to take a look, probably only a 4hr round trip drive so no not bad. I was the first one to respond early this AM, when he responded to my email(phone call) he said he knows I will be driving a bit so he's holding it for me for "first chance" tomorrow morning when he is showing it. He also stated he has had a lot of responses after my early call.

What of you think?

thanks, Brian

It was the sellers father in law who as a retired machinist bought this for home use(probably not the original owner). The seller does not know anything about lathes, it in his mom's garage and she wants it gone. Condition in the pics looks pretty good but hard to tell, accessories and tooling are a question but everything on the bench is included. Correct me if I'm mistaken but I believe this Taiwan made early 80s(?) Jet has hardened ways and is substantially heavier than the Atlas, and has a !.5" spindle(almost 2x the Atlas). Any weirdness associated with this era/model of Jet? Not sure what the PS means, I googled it but didn't find anything specific regarding it. They're only asking $500 for it, so I almost feel obligated to take a look, probably only a 4hr round trip drive so no not bad. I was the first one to respond early this AM, when he responded to my email(phone call) he said he knows I will be driving a bit so he's holding it for me for "first chance" tomorrow morning when he is showing it. He also stated he has had a lot of responses after my early call.

What of you think?

thanks, Brian