- Joined

- Jul 13, 2014

- Messages

- 1,051

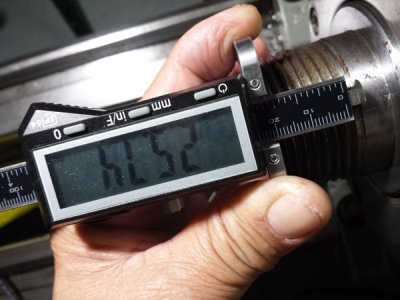

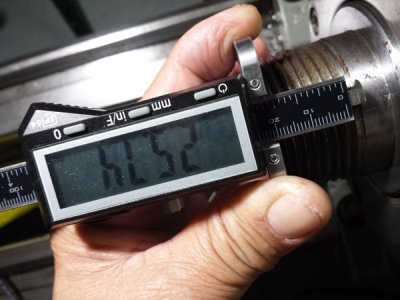

I was gifted this lathe, no motor, no chuck, and the rest of the machine is not bad. I got the motor part under control, picked up a TECO VFD and 1 HP WEG motor, the chuck is another story. The spindle nose thread is not the common variety, some people I talked to claim it is 2 inches x 8 TPI, others say it is 50MM x 8 TPI. I took some pictures of the spindle nose and posted them in the WTB, but got no bites, maybe taking the discussion in this section might generate some traffic and hopefully someone can direct me to the right place to get the proper back plate, Or even better if someone has one laying around doing and willing to sell it.

I am desperate...

One option is to machine one once my 1236 is up and running. I have no problem boring and threading a blank back plate and making some cuts to get it all squared up. Since I have not done this work before , I am not sure on a couple of things; 1. How does the back plate bottoms out, against the spindle face, or thread on thread? 2. How much radial clearance should I cut the back plate for the unthreaded section of the nose (don't know the proper name) when back plates screws in? 3. Should I put a hold screws on the back plate to keep it in place in case I run the lathe in the reverse? Would the hold down screw create an imbalance situation?

Here are the pictures of the spindle nose.

What is the correct thread size for this spindle nose

Thank you.

I am desperate...

One option is to machine one once my 1236 is up and running. I have no problem boring and threading a blank back plate and making some cuts to get it all squared up. Since I have not done this work before , I am not sure on a couple of things; 1. How does the back plate bottoms out, against the spindle face, or thread on thread? 2. How much radial clearance should I cut the back plate for the unthreaded section of the nose (don't know the proper name) when back plates screws in? 3. Should I put a hold screws on the back plate to keep it in place in case I run the lathe in the reverse? Would the hold down screw create an imbalance situation?

Here are the pictures of the spindle nose.

What is the correct thread size for this spindle nose

Thank you.