Hello Ted,

Thank you for your comment. I was of the, it seems, mistaken impression that some machines, particularly Bridgeport, had this flexibility. I was unaware of the single voltage, single speed motor fitted to some of these machines.

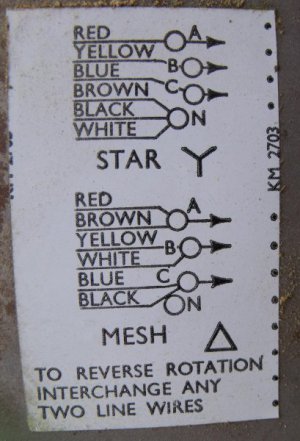

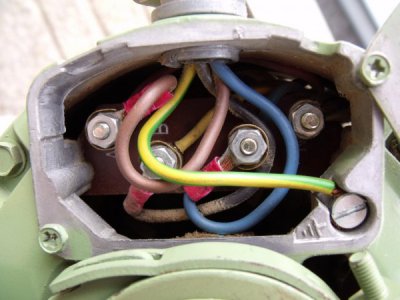

However I have knowledge of a number of people that have taken the trouble to make modifications to motors that didn't provide facilities for the user to alter the wiring configuration in a simple way. These users have altered the winding configuration internal to the motor and brought both ends of the three stator windings out so that they can use 440 volt star wired motors in delta on 220/240 volt supplies from VFD.

But if you don't have the knowledge or the skills to do this yourself, taking the motor to a motor rewinder and letting them do it for you, would be one way.