- Joined

- Jun 12, 2014

- Messages

- 401

Thanks Mark!

I got this switch on Ebay for 12 bucks. it is all self contained like a little magnetic starter. The switch buttons are momentary and there is a little coil in the switch so when you shut it off it breaks both lines instead of just the power line. The big stop paddle can be removed but that was on reason I got it. I am going to be putting these on all my machines. As soon as I get the fingers on my brake ( which I am working on now), I will bend covers to enclose the motor.

I got this switch on Ebay for 12 bucks. it is all self contained like a little magnetic starter. The switch buttons are momentary and there is a little coil in the switch so when you shut it off it breaks both lines instead of just the power line. The big stop paddle can be removed but that was on reason I got it. I am going to be putting these on all my machines. As soon as I get the fingers on my brake ( which I am working on now), I will bend covers to enclose the motor.

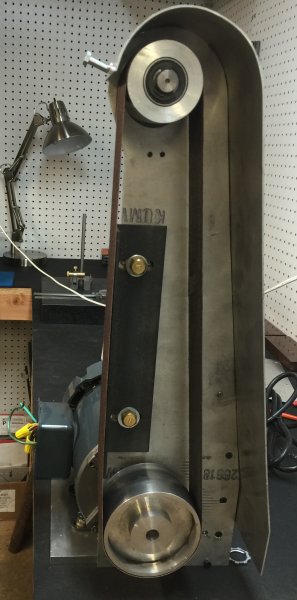

I added this gusset to the frame. It is a piece of 1/4" aluminum plate. The aluminum frame tipped out about an 1/8" at the top when the belt tension was applied. This was overcome by adjusting the tracking. It worked but I didn't like it. This gusset eliminated the problem. Now everything is all lined up as it should be , the sander runs better and looks much better. This motor is a ball bearing motor ( the old one was not). I'm going to contradict myself a little here. This new motor is 3450 rpm. Twice the speed of the old one. Originally , I calculated the SFM according to the belt manufacturers recommendations. This fast speed works great on steel, but can be to fast for aluminum if you aren't carefull. Also it will wear a really course belt such as 40 or 60 grit really quickly. This won't be a problem because I will be using 120 and 180 grit belts. I have another sander for 40 and 60 grit that runs slower. The course belt can be used here but it's life will be a little shorter. So , my conclusion is you can run either speed and have good results. I have to design a new table setup though. The original won't fit. I'm going to look up another build on here because he used a great table setup. ( I just have to find it again). I was happy with this sander before but am really happy now.

I added this gusset to the frame. It is a piece of 1/4" aluminum plate. The aluminum frame tipped out about an 1/8" at the top when the belt tension was applied. This was overcome by adjusting the tracking. It worked but I didn't like it. This gusset eliminated the problem. Now everything is all lined up as it should be , the sander runs better and looks much better. This motor is a ball bearing motor ( the old one was not). I'm going to contradict myself a little here. This new motor is 3450 rpm. Twice the speed of the old one. Originally , I calculated the SFM according to the belt manufacturers recommendations. This fast speed works great on steel, but can be to fast for aluminum if you aren't carefull. Also it will wear a really course belt such as 40 or 60 grit really quickly. This won't be a problem because I will be using 120 and 180 grit belts. I have another sander for 40 and 60 grit that runs slower. The course belt can be used here but it's life will be a little shorter. So , my conclusion is you can run either speed and have good results. I have to design a new table setup though. The original won't fit. I'm going to look up another build on here because he used a great table setup. ( I just have to find it again). I was happy with this sander before but am really happy now.Mark , is there enough support for the table with the thin aluminum frame. I think it may be the reason for the gouging .

How are you , still working hard in your shop .