- Joined

- Mar 29, 2015

- Messages

- 19

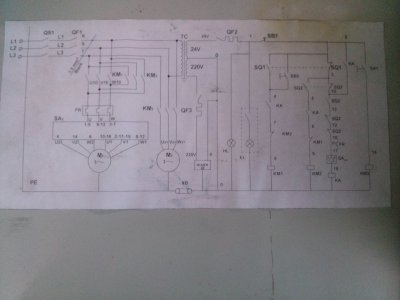

Hi Jim , found this schematic.I had to do some research on 240/415 3 phase. Never used it or heard of it before. Was it only the transformer burned out? I may have misunderstood your original post. From what I see you needed the neutral at the lathe for the coolant transformer. One leg of the 415 to neutral will supply 240 volts to the transformer unless the transformer is dual voltage input then you can use two legs and change the input taps. A schematic of the control box would be helpful.

Could you have a look and see what you think.

I think I was correct with my way, I have no idea how the electrician wired it.

Thanks

Thanks PhilWhat type of lathe, and is the work lamp a Lovolite? some lovolite transformers used two phases and stepped down to 24v (some were 50v I think), some used phase to neutral (240V) It may have burned because it was a phase to neutral model that has been wired across two phases (415V) Very unusual to have a 3 phase lathe with a 240v pump and light, without the wiring being totally seperate, can you post up some pics?

Phil

I have made a few mistakes, sorry. The transformer is 415v In 220v/24v out . The coolant pump is 415v single,The Light 24v Halogen no branding , DRO 220v. The lathe is a Hafco Metalmaster AL-356. I am going to lift the lathe out today and then I will take some pics. The transformer will be Tuesday , I guess I will put it in and try it.

Thanks

Brendan