- Joined

- Jan 2, 2014

- Messages

- 8,852

Recently one of the three knobs came right off my drill press quill handle.

It is a plastic knob with a rubber grip coating.

The plastic barrel was cracked and broke out:

Looking at the other two knobs they are no better:

Since the ball-turner for the lathe is still on the long project "to-do" list, and I am just starting to feel almost, slightly comfortable with Fusion-360, I decided to 3D print some new ones.

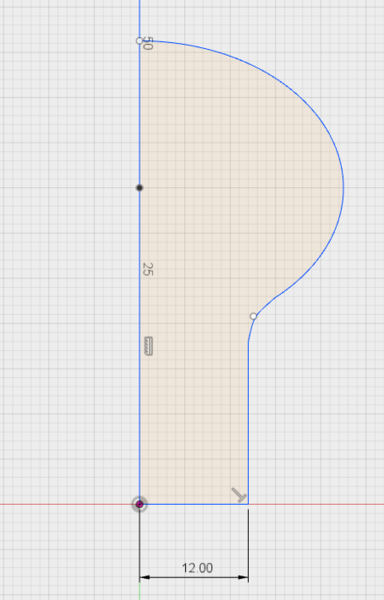

I drew a flat cross section:

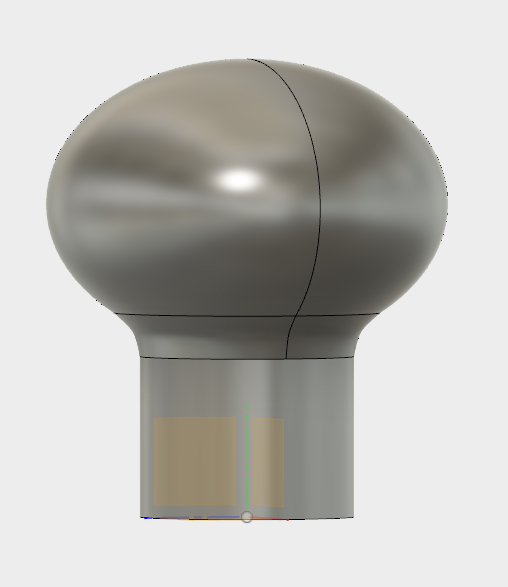

I rotated it about the centre line:

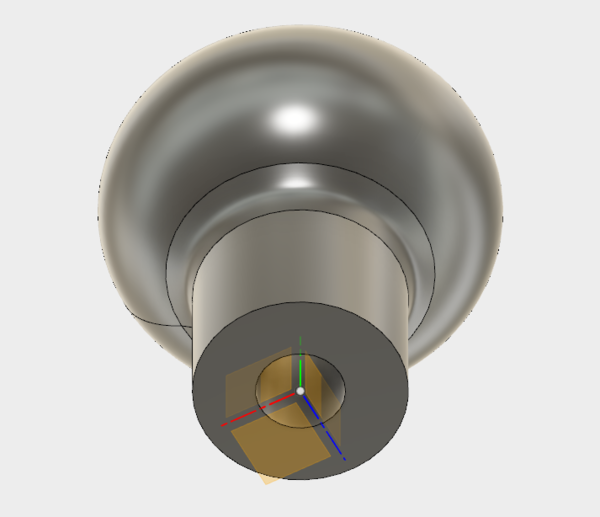

and added a 10mm dia. hole in the bottom:

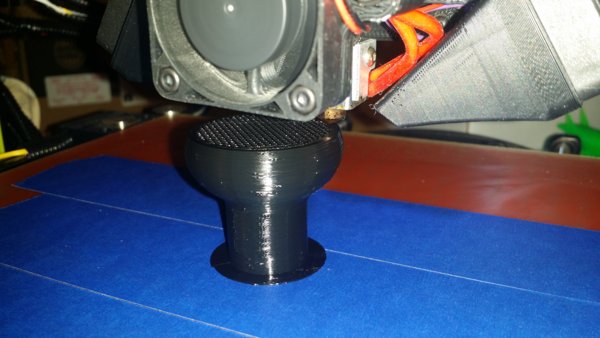

Here it is during printing:

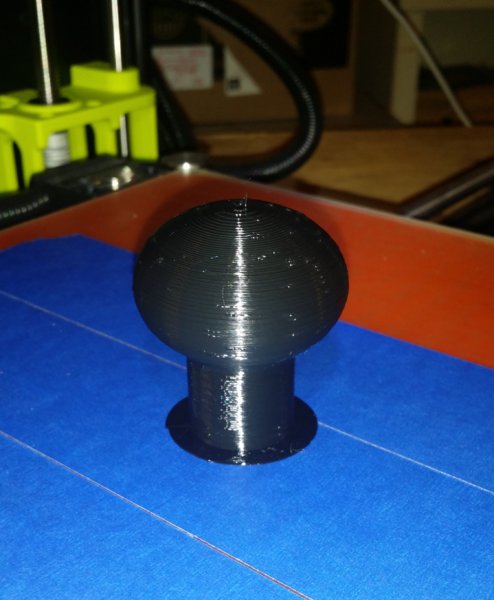

Done printing:

Then I tapped them M12x1.75 and installed them:

-brino

It is a plastic knob with a rubber grip coating.

The plastic barrel was cracked and broke out:

Looking at the other two knobs they are no better:

Since the ball-turner for the lathe is still on the long project "to-do" list, and I am just starting to feel almost, slightly comfortable with Fusion-360, I decided to 3D print some new ones.

I drew a flat cross section:

I rotated it about the centre line:

and added a 10mm dia. hole in the bottom:

Here it is during printing:

Done printing:

Then I tapped them M12x1.75 and installed them:

-brino