I have a Starrett edge finder for finding my X and Y zero but I have to adjust the spindle speed to something less than 800 rpm. Kind of a pain on my CNC mill to change pulley speeds. And then I have to deal with setting the Z zero. That takes another tool and another step in the setup sequence. I also have a XYZ tool setter that is automated through Mach3 (see picture below). It works well for setting up rough stock but is lacking accuracy when locating semi-finished parts for second operation machining.

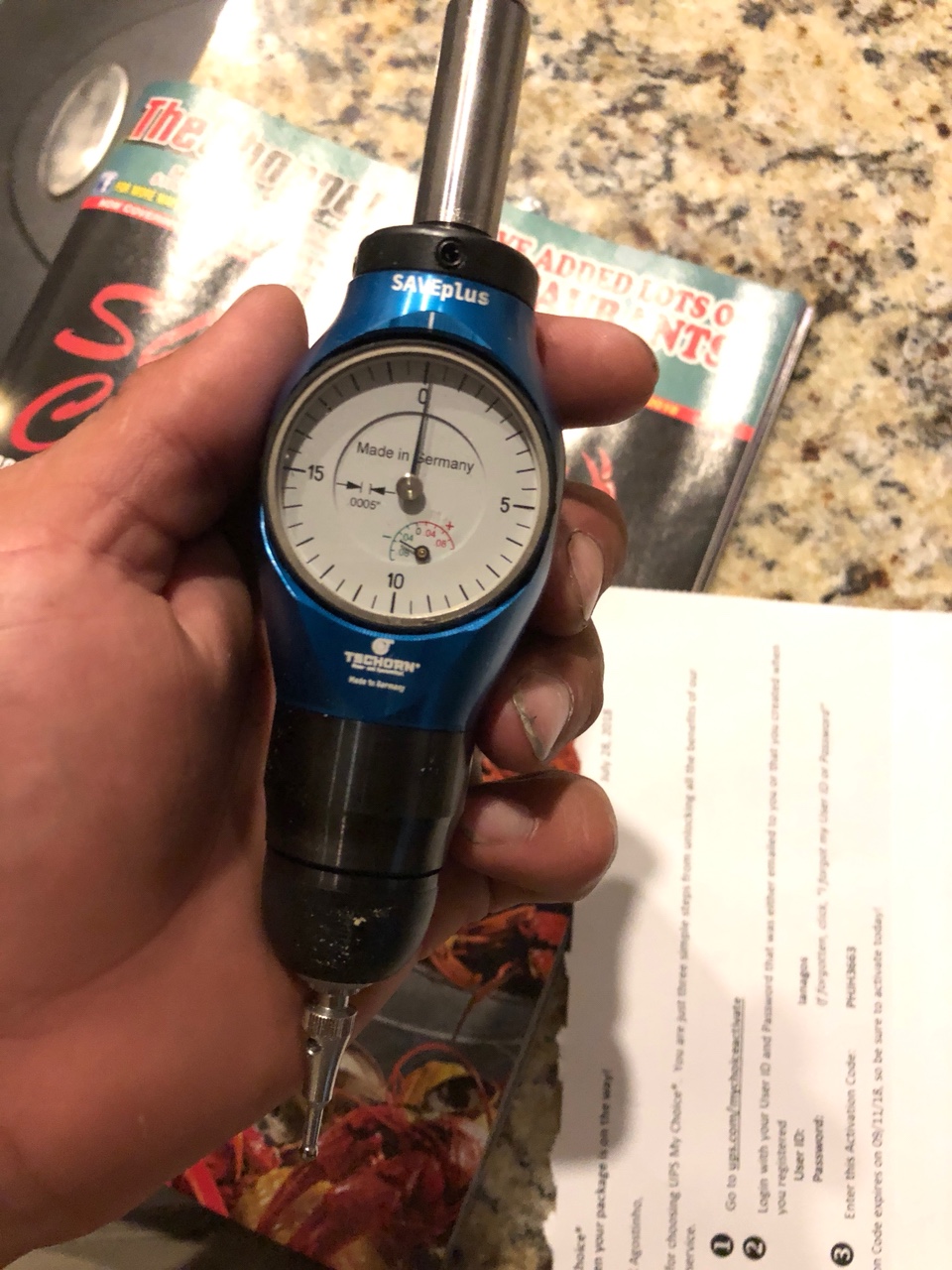

I've been thinking about purchasing a 3D taster for locating parts edges and top surfaces. I've never used one but have viewed several videos showing them in action. On the surface they appear to be accurate and easy to use. The down side is they are expensive. I've looked at Tschorn, Haff and Schneider, SPI (looks like a Tschorn copy) and Haimer. Haimer seems to be the most popular and Tschorn the least expensive. Anyone have hands on experience and an opinion as to their usefulness? How accurate are they in use? Is any brand better than the other in regards to accuracy, repeatability, durability, etc?

I've been thinking about purchasing a 3D taster for locating parts edges and top surfaces. I've never used one but have viewed several videos showing them in action. On the surface they appear to be accurate and easy to use. The down side is they are expensive. I've looked at Tschorn, Haff and Schneider, SPI (looks like a Tschorn copy) and Haimer. Haimer seems to be the most popular and Tschorn the least expensive. Anyone have hands on experience and an opinion as to their usefulness? How accurate are they in use? Is any brand better than the other in regards to accuracy, repeatability, durability, etc?