- Joined

- Jan 2, 2019

- Messages

- 6,509

So, I'm at the point where my CNC mill/drill project is just about ready to start making actual parts and I think I need to buy a 4" milling vise to replace the hardware store drill press vise I've been using to test. My table is flat cast aluminum and I have some more cast pieces that I think will eventually be drilled and tapped for sacrificial workholding fixtures which I'll use with hex clamps but I know I'll want a decent vise for quick set-ups.

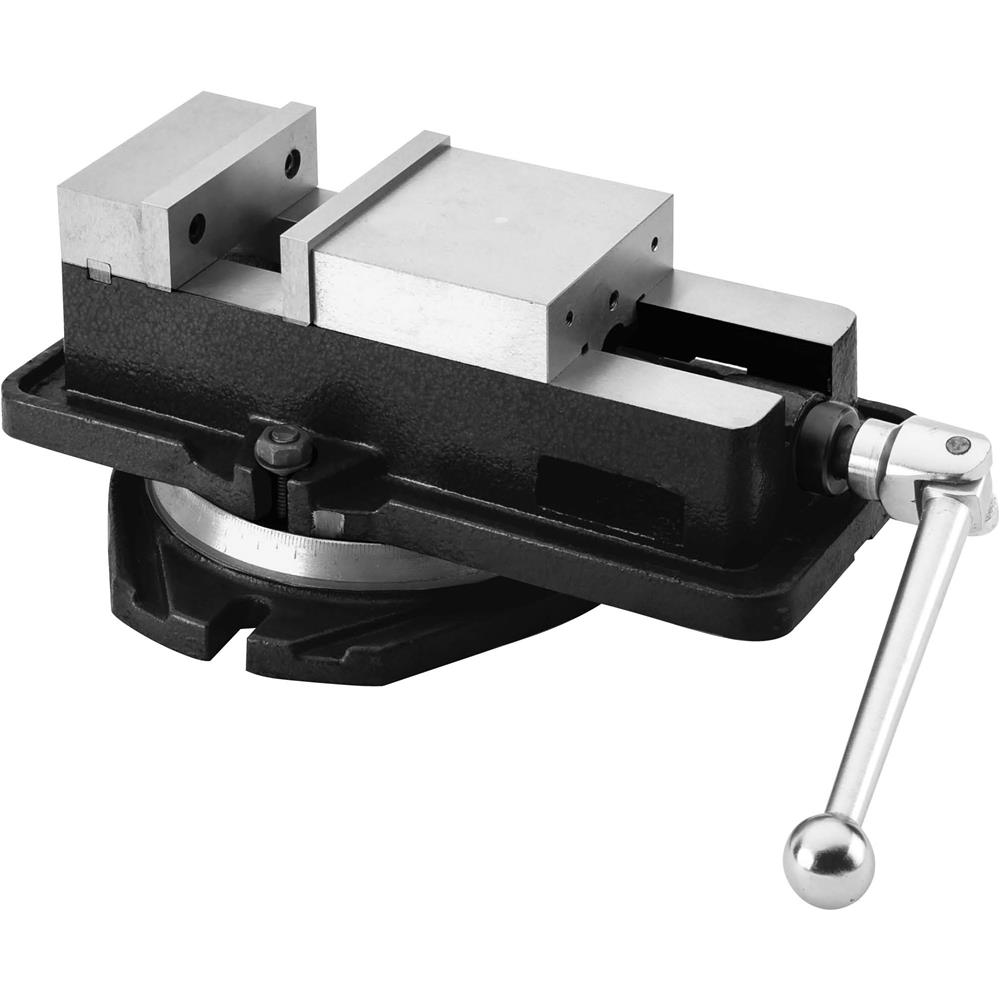

Looking at Shars think I've ruled out the $150 model so I'm down to the $250 "CNC" vise

https://www.shars.com/products/workholding/vise/4-440v-cnc-milling-machine-vise-0-0004-1

or this one for $75

www.shars.com

www.shars.com

While I'd like to just buy the more expensive one my budget tells me to go with the cheapie. I figure it will be a while still before I'm likely to be splitting tenths with this machine if ever, and "good enough" will be just fine until then. I already have a China built 6" HF vise I've never put on a machine but it seems like it would work if it was just a little smaller. The $250 vise from Shars has a wider jaw opening but I don't see that as a major limitation for my use and probably not worth the extra $175 in itself.

Thoughts?

BTW, here's the machine as it sits now.

Thanks,

John

Looking at Shars think I've ruled out the $150 model so I'm down to the $250 "CNC" vise

https://www.shars.com/products/workholding/vise/4-440v-cnc-milling-machine-vise-0-0004-1

or this one for $75

4'' x 3.93" Lock Down Precision Milling Machine Vise

While I'd like to just buy the more expensive one my budget tells me to go with the cheapie. I figure it will be a while still before I'm likely to be splitting tenths with this machine if ever, and "good enough" will be just fine until then. I already have a China built 6" HF vise I've never put on a machine but it seems like it would work if it was just a little smaller. The $250 vise from Shars has a wider jaw opening but I don't see that as a major limitation for my use and probably not worth the extra $175 in itself.

Thoughts?

BTW, here's the machine as it sits now.

Thanks,

John

Last edited: