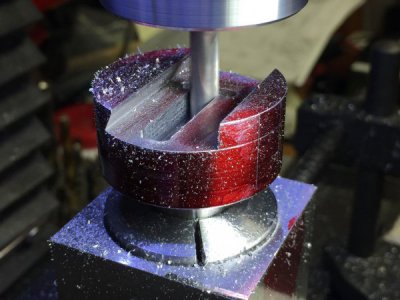

I am about to begin making a boring head for my SX2 mill. I will be using one of the numerous plans available to build the boring head but I have ran into an issue with the dovetail angle. Everybodys plans require a 45 degree dovetail be cut into the body and slide. I do not have a 45 degree dovetail cutter but I do have a 60 degree indexable dovetail cutter that I made using a single TCMT style insert similar to what Randy Richards makes. Can I cut the dovetails 60 degrees and not have any issues? I have read one persons opinion on dovetails that 45 degree is better for slideways that get clamped and they hold better to the radial and axial loads but I haven’t really seen any proof. I would assume that 60 degrees will be fine as long as my design allows for a proper amount of material to support the dovetail.

What are your alls opinions on this? All of the plans I have seen call for a 45 degree dovetail. Has anyone built a boring head using 60 degree dovetails or has anyone seen any plans for one that uses a 60 degree dovetail?

My other option is to build another indexable dovetail cutter that cuts 45 degree dovetails using a TCMT style insert. I see that Dorian makes a 45 degree indexable dovetail cutter that uses triangular inserts like the TCMT. Link here>>> https://www.ebay.com/p/Dovetail-Mil...8%26rvr_ts%3De2bf799e1640a9c55117a2eafff7d0bb I assume I could angle the insert to give me the correct angle but the bottom of the insert would only make contact on the outer edge. Before anyone says it, I am not wanting to purchase a 45 degree dovetail cutter. I am unemployed at the moment and would prefer to not spend anymore money on this project.

Lastly, if anyone has any boring heads plans they would recommend similar to the 2” Criterion round style head please post a link or info to help me find it.

What are your alls opinions on this? All of the plans I have seen call for a 45 degree dovetail. Has anyone built a boring head using 60 degree dovetails or has anyone seen any plans for one that uses a 60 degree dovetail?

My other option is to build another indexable dovetail cutter that cuts 45 degree dovetails using a TCMT style insert. I see that Dorian makes a 45 degree indexable dovetail cutter that uses triangular inserts like the TCMT. Link here>>> https://www.ebay.com/p/Dovetail-Mil...8%26rvr_ts%3De2bf799e1640a9c55117a2eafff7d0bb I assume I could angle the insert to give me the correct angle but the bottom of the insert would only make contact on the outer edge. Before anyone says it, I am not wanting to purchase a 45 degree dovetail cutter. I am unemployed at the moment and would prefer to not spend anymore money on this project.

Lastly, if anyone has any boring heads plans they would recommend similar to the 2” Criterion round style head please post a link or info to help me find it.