Hi everyone,

I am getting ready to build a 4th axis for my CNC mill. I should be getting the rotary table in the mail in about a week. I will be posting pictures as I go along .

.

The rotary table is one from eBay. It is of the 8" variety. I believe the brand is CME.

The servo and drive is from Leadshine and is 400w.

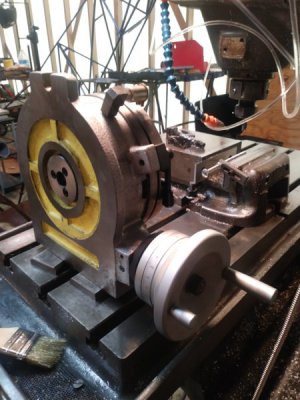

Here are a couple pictures of the servo and drive:

I am getting ready to build a 4th axis for my CNC mill. I should be getting the rotary table in the mail in about a week. I will be posting pictures as I go along

The rotary table is one from eBay. It is of the 8" variety. I believe the brand is CME.

The servo and drive is from Leadshine and is 400w.

Here are a couple pictures of the servo and drive: