- Joined

- Oct 30, 2016

- Messages

- 155

Hi fellas,

Another question I've noticed that its possible to buy 5C step collets which I think they are collets closing on the OD of work pieces in over size. From what I can tell they can be machined to the ID desired.

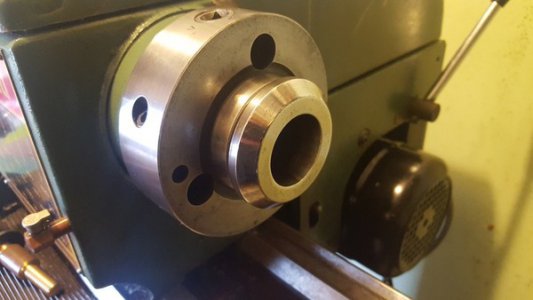

here's an example

But when I see the step collets for sale they never show, or offer, the collar that goes around the outside of the diameter of the oversize collet head to close it and hold it tight.

Here's an example

Does anyone know if such a thing is available for a lathe like Southbend, or will it be like the adaptor I have in my spindle with the needed size to encompass the step collet head?

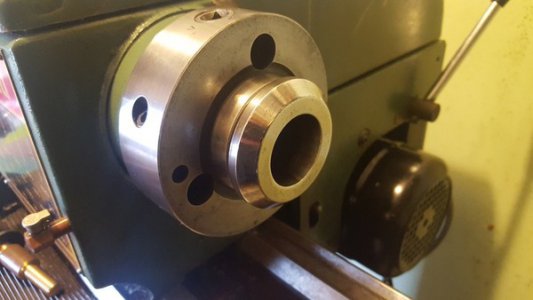

Hers's the adaptor in my spindle that allows me to hold 5C collets.

Any help appreciated.

Another question I've noticed that its possible to buy 5C step collets which I think they are collets closing on the OD of work pieces in over size. From what I can tell they can be machined to the ID desired.

here's an example

But when I see the step collets for sale they never show, or offer, the collar that goes around the outside of the diameter of the oversize collet head to close it and hold it tight.

Here's an example

Does anyone know if such a thing is available for a lathe like Southbend, or will it be like the adaptor I have in my spindle with the needed size to encompass the step collet head?

Hers's the adaptor in my spindle that allows me to hold 5C collets.

Any help appreciated.