- Joined

- Apr 12, 2013

- Messages

- 562

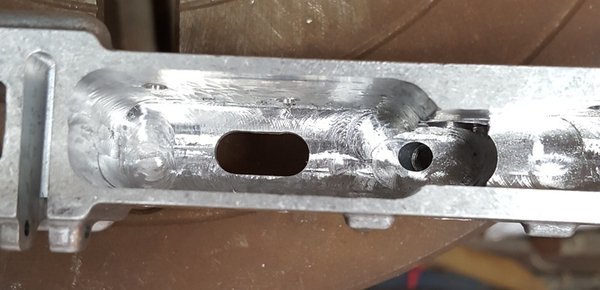

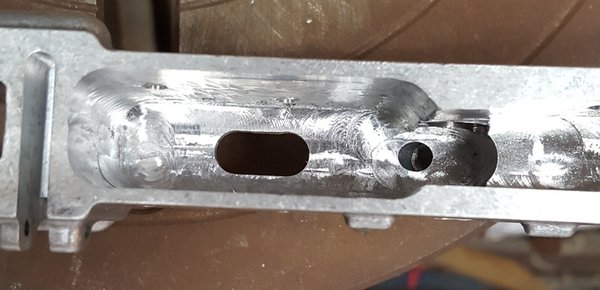

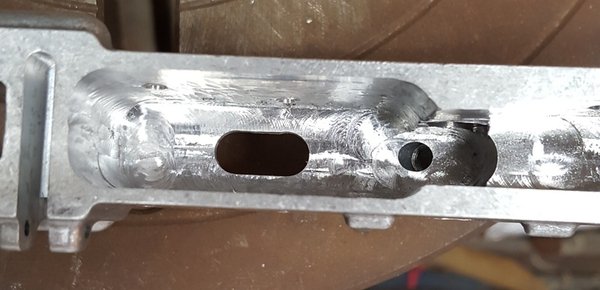

Plan A is a bust...the throat of my milling attachment is about 1/4" too narrow to fit the jig with the receiver installed. Since I don't want to try and thin the jig or open up the milling vise, I'm on to plan B, lots of shims/blocks/etc on a t-slot cross slide I am finishing the fit up on.