- Joined

- Nov 25, 2015

- Messages

- 8,209

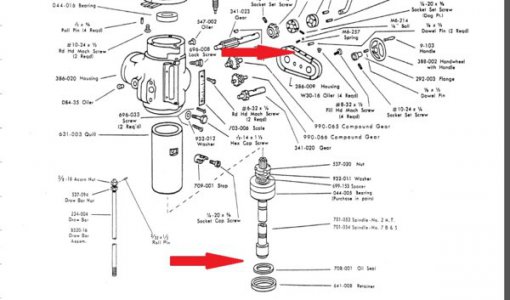

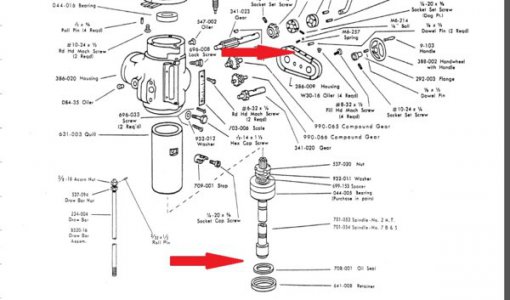

I have 2 manuals that I got from vintage machinery.org One for the 8520, the other 8530.

Neither have the correct spindle diagram, since both don't even show the bottom bearings, only the top bearings. Since that's one of the most important bearings, its a big oversight.

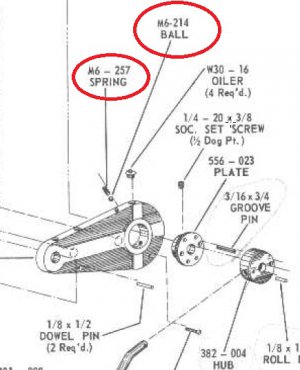

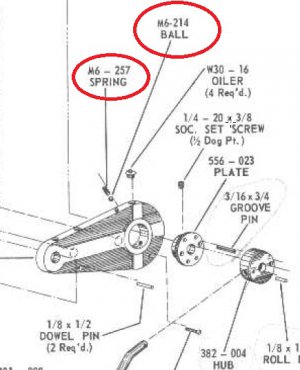

My problem is I am ready to clean the quill feed, There's a ball detent to hold the in/out on the course feed, so it engages the fine or disables the fine feed. Both manuals show 3 oilers on top, and 1 hole with a ball , spring and set screw. Well, there's 3 oilers but no place for the spring detent... So where is it? They couldn't drill a blind hole. The small oiler has to be too small , and it doesn't seem like a good idea to use a pressed in oiler to hold the quill detent. These are real small oilers.. Anyone have any experience with this???

It needs to be cleaned while I'm in... Also does anyone have a part number for a seal on the quill nut. Clausing wanted a ridiculous amount of money for a seal.. so I am not buying from Clausing.

Neither have the correct spindle diagram, since both don't even show the bottom bearings, only the top bearings. Since that's one of the most important bearings, its a big oversight.

My problem is I am ready to clean the quill feed, There's a ball detent to hold the in/out on the course feed, so it engages the fine or disables the fine feed. Both manuals show 3 oilers on top, and 1 hole with a ball , spring and set screw. Well, there's 3 oilers but no place for the spring detent... So where is it? They couldn't drill a blind hole. The small oiler has to be too small , and it doesn't seem like a good idea to use a pressed in oiler to hold the quill detent. These are real small oilers.. Anyone have any experience with this???

It needs to be cleaned while I'm in... Also does anyone have a part number for a seal on the quill nut. Clausing wanted a ridiculous amount of money for a seal.. so I am not buying from Clausing.