-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

9 x 20 half nut problem

- Thread starter savarin

- Start date

- Joined

- Feb 9, 2017

- Messages

- 5,231

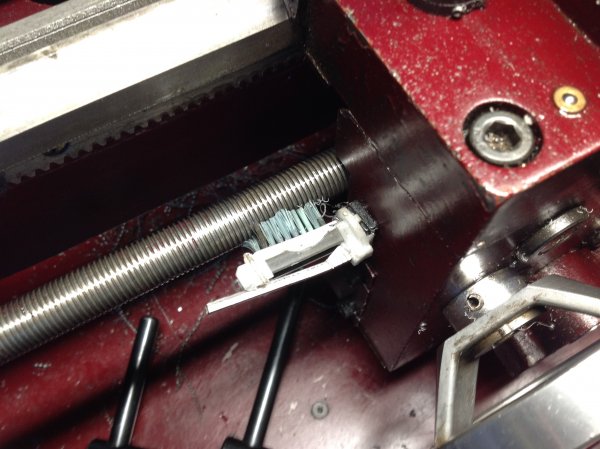

My 9x20 had the half nuts not set up correctly so that's why they wore quickly. Don't know if it was previous owner or factory. I replaced them with Grizzley units. Like Savarin in order to get the correct alignment had to set the half nuts and then tighten the saddle. I also rigged an old tooth brush to clean the lead screw but wasn't really happy with the mount. I recently came up with something better. Still a tooth brush but old brushes off our SoniCare brushes that have really strong magnets in the base. This really simplifies mounting after modding the brush. This seems to knock all the swarf off the lead screw. I also put a bellows between the carriage and under the chuck and it overhangs the side eliminating the amount of swarf that can even get slung onto the lead screw.

- Joined

- Dec 2, 2012

- Messages

- 1,721

Two thoughts on your rapid wear of the half nuts. First, with the longitudinal slot and sharp edges, it may be working like a tap shaving away the half nut threads. Second, if the half nuts are not completely disengaged when in the power feed mode, the sharp edges of the threads may be shaving the threads. An examination of the wear pattern should tell you which.

my old 9x20 only has the half nuts for power feed so that put a lot of extra ware on them.

Stu

- Joined

- Aug 22, 2012

- Messages

- 4,100

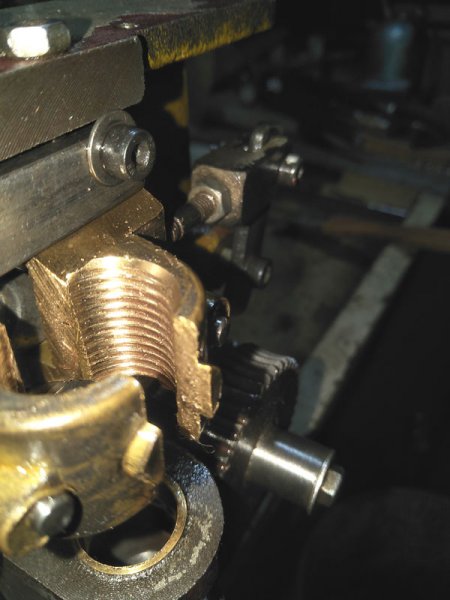

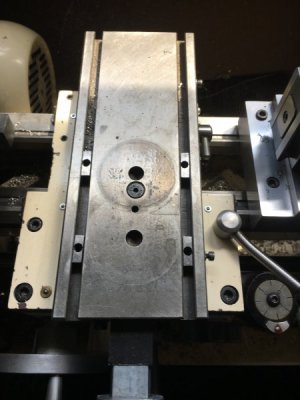

Heres a pic of the worn half nut, it looks ok in the pic but theres virtually no real thread left.

Whilst awaiting the new ones I thought I should clean and adjust as much as I could.

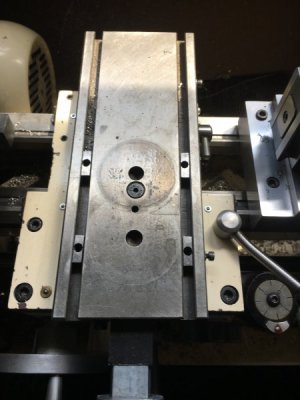

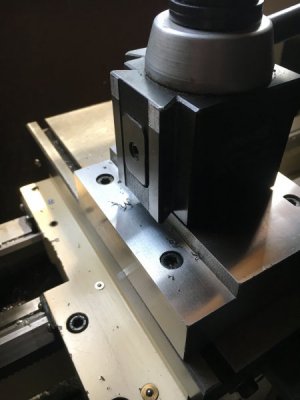

Todays job was to check out the cross slide, it had a tiny rock between two corners.

A bit of scraping got it sitting flat with full contact for the full length.

Next I will be drilling and tapping for two more gib screws.

Now another question, Would this be a good idea and worth doing to improve cross slide oiling?

Grinding out hollows on the black lines and feeding them with a ball oiler, if so how many oilers per side?

and Is there a better pattern?

Whilst awaiting the new ones I thought I should clean and adjust as much as I could.

Todays job was to check out the cross slide, it had a tiny rock between two corners.

A bit of scraping got it sitting flat with full contact for the full length.

Next I will be drilling and tapping for two more gib screws.

Now another question, Would this be a good idea and worth doing to improve cross slide oiling?

Grinding out hollows on the black lines and feeding them with a ball oiler, if so how many oilers per side?

and Is there a better pattern?

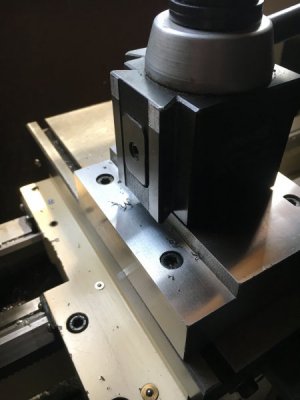

Savarin that is a good way to get oil on the slides. I would recommend not so many zigzags. I did this exact mod about a year ago on my jet 9x20. I ended up doing my saddle which for the V groove I put the Oiler directly above the v to get both sides. Then for the flat part I did what your doing. I put three perpendicular lines almost the width of slide. Then connected each groove with a long angled groove that went from top to bottom of groove. Like this |\|\|. Only as long as slide. I put oilers at each end also. The trick is to not break through the sides so the oil has a void to stay in. The mod worked great and the fact that their were no provisions for oil. Oiling the flat rail made a big difference for me with saddle movement. It now glides as it should. What’s nice is after filling ports you can see how the wipers contain and spread the oil from the inside. Not mixing oil with chips moving slides hoping it gets under there.

Oh and you want to try and cover the whole area of the slide with the groove. Meaning any spot that has no groove running over it will wear different so it might wear a ledge on sliding surface. Like putting a line parallel with slide. The opposite part would never wear causing a ledge and problems in the future. That’s why the angle going the width of slide is a better option just watch your ends.

Oh and you want to try and cover the whole area of the slide with the groove. Meaning any spot that has no groove running over it will wear different so it might wear a ledge on sliding surface. Like putting a line parallel with slide. The opposite part would never wear causing a ledge and problems in the future. That’s why the angle going the width of slide is a better option just watch your ends.

- Joined

- Feb 1, 2015

- Messages

- 9,572

Yes, the same as my Grizzly 602 and my Atlas/Craftsman 6 x 18.my old 9x20 only has the half nuts for power feed so that put a lot of extra ware on them.

Stu

The Grizzly 9 x 19 (G4000) and IIRC, the Enco and HF as well, do have the separate feed system. Savarin had mentioned the keyway that is characteristic of the separate feed so presumably the half nuts are only engaged for threading. Which is why is would be puzzling to see so much wear on the half nuts.

If the half nuts didn't completely disengage when the power feed was being used, they would be sliding over those sharp lead screw threads which would be wearing them down.

- Joined

- Dec 2, 2012

- Messages

- 1,721

Yes, the same as my Grizzly 602 and my Atlas/Craftsman 6 x 18.

The Grizzly 9 x 19 (G4000) and IIRC, the Enco and HF as well, do have the separate feed system. Savarin had mentioned the keyway that is characteristic of the separate feed so presumably the half nuts are only engaged for threading. Which is why is would be puzzling to see so much wear on the half nuts.

If the half nuts didn't completely disengage when the power feed was being used, they would be sliding over those sharp lead screw threads which would be wearing them down.

Ow yes now you say that I did indeed miss that in his post

Stu

- Joined

- Feb 9, 2017

- Messages

- 5,231

Seems like some kind of drip cup that drips oil on either the half nut or lead screw would be a good idea. As little single point threading as I do that half nut should last forever as its only engaged for threading. It also seems like a good idea to get the proper die for the lead screw and chase the threads. Maybe take a look at the power feed to see if it's somehow causing that slot in the lead screw to develope a burr while in use. That's one thing I've noticed with this 9x20, lots of attention to all the details because of the variable QC. Like the half nuts not being properly adjusted in the first place. Just never know what's going to bite you in the butt until it's too late.