- Joined

- Feb 2, 2014

- Messages

- 1,055

Yesterday because of the oil deluge I had I replaced all the gaskets and this time I used some silicone sealant on them as well.

No oil leaks found so far and I will keep my fingers crossed that none will show up later.

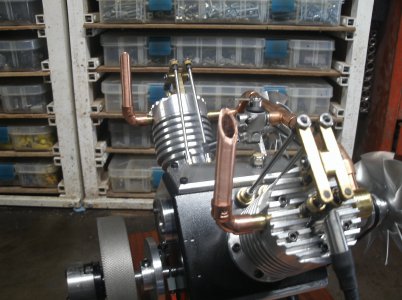

First I checked the valves for sealing and was happy to find them in great shape so I installed the cylinder heads on the engine. The lifters fit without any modifications but the push rods all needed to be shortened. I set the valve timing as close as possible for now and tightened the cams in place.

I also mounted a flywheel so I could turn the engine over by hand but this is not the one I will be using for this engine. I do have a larger one in mind.

Today I made up and installed the intake manifold and carburetor. I used copper pipe fittings with o-rings on two of the joints so I could remove the manifold later if need be.

I am trying to decide if I like the copper color or should I paint the manifold maybe black?

Do you have an opinion?

Thanks for looking

Ray

No oil leaks found so far and I will keep my fingers crossed that none will show up later.

First I checked the valves for sealing and was happy to find them in great shape so I installed the cylinder heads on the engine. The lifters fit without any modifications but the push rods all needed to be shortened. I set the valve timing as close as possible for now and tightened the cams in place.

I also mounted a flywheel so I could turn the engine over by hand but this is not the one I will be using for this engine. I do have a larger one in mind.

Today I made up and installed the intake manifold and carburetor. I used copper pipe fittings with o-rings on two of the joints so I could remove the manifold later if need be.

I am trying to decide if I like the copper color or should I paint the manifold maybe black?

Do you have an opinion?

Thanks for looking

Ray