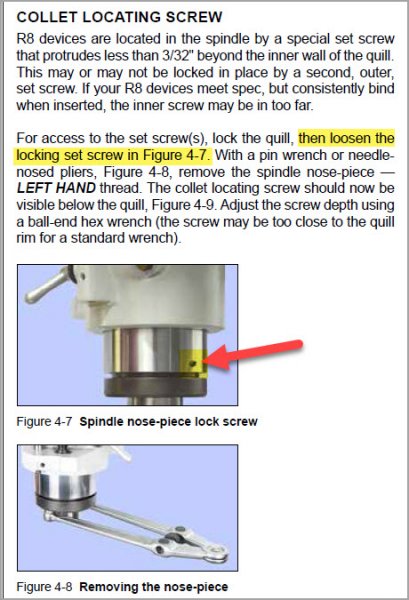

On the PM website is a nice PDF guide for 935 mill with pictorial instructions to adjust the depth of the collet locating screw. That part of the procedure is straightforward. But before that, the disassembly sequence begins by removing a set screw on the quill housing & then unscrewing the nose piece with 2 pin spanner wrench on the underside.

But my question is - what exactly is this set screw engaging? It almost appears to be lining up with the threads on the nose piece itself which would seem like a dubious way to secure it (potentially marring threads just by tightening)? Or am I misinterpreting the dimensions & it lands at some safe part of the nose piece?

But my question is - what exactly is this set screw engaging? It almost appears to be lining up with the threads on the nose piece itself which would seem like a dubious way to secure it (potentially marring threads just by tightening)? Or am I misinterpreting the dimensions & it lands at some safe part of the nose piece?