-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

935 table rubber T-slot ends

- Thread starter petertha

- Start date

- Joined

- Jan 31, 2016

- Messages

- 11,423

2 things . They keep chips from entering the end of the tee slots ( which are a pita to clean out ) , and also act as coolant dams if your machine has a drain in the back . I can't see the back but most likely you have them .

- Joined

- Jul 2, 2014

- Messages

- 7,594

I am confused. Chips usually enter the t-slots from the top, not from the ends. Also, if I am using coolant, I want it to drain, not become an overflowing lake in the t-slots. Please help me to understand this...

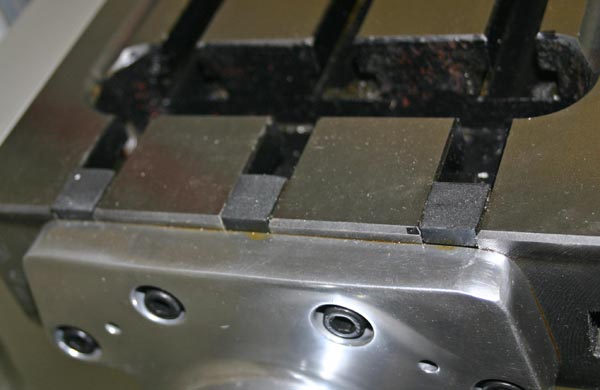

I probably should have qualified - mine is a '935' mill, not PM-935. Suspect the same machine but since I thought I saw same rubber on PM machines figured I'd ask here. Anyway this shows the rubber & how it stands proud of mill table which I find odd. I'd rather have it flush or recessed so table protection mats don't rise up on the ends or any chance of misaligned extended stock. My table also has a threaded coolant hole in both L&R pocket so the damn/diversion makes sense. I don't use flood right now so they are basically open.

- Joined

- Nov 27, 2012

- Messages

- 7,852

I probably should have qualified - mine is a '935' mill, not PM-935. Suspect the same machine but since I thought I saw same rubber on PM machines figured I'd ask here. Anyway this shows the rubber & how it stands proud of mill table which I find odd. I'd rather have it flush or recessed so table protection mats don't rise up on the ends or any chance of misaligned extended stock. My table also has a threaded coolant hole in both L&R pocket so the damn/diversion makes sense. I don't use flood right now so they are basically open.

That hole does look like for coolant drain if it goes all the way through to the recess in the table. And if it does then that's probably what those rubber pieces are for, plugs to help stop coolant from flowing out the sides of the table.

My inclination was to trim them flush but I'll look closer. Maybe a simple matter of sliding them out & remove altogether so nothing stands proud since I think we are agreeing they are to damn flood fluid from leaking out the end. Maybe they are a generic T-item & just so happen to stick up on this table..

- Joined

- Dec 26, 2015

- Messages

- 2,079

My PM935 is the same as yours Peter. My guess is that they machined the t-slots in the table straight through from one end to the other to reduce the manufacturing complexity of plunging down into the coolant well at one end, and pulling out in the well at the other end. Then they filled the t-slots between the coolant wells and the ends of the table with a rubber compound that was designed to swell in place to prevent leaks, and then didn't trim the tops flat. I intend to trim mine just below the surface of the XY table.

- Joined

- Jul 2, 2014

- Messages

- 7,594

My Millrite table has slots to the table ends, but also have end caps with cavities in them to catch the coolant. Then end caps have threaded drain holes in them. No rubber required, and glad mine does not have them.

- Joined

- Dec 26, 2015

- Messages

- 2,079

You can see what Peter's talking about here:

Yeah, those just look like they want to keep water from getting behind the end cap to the lead screw. The Millrite end cap above is nice, but a much bigger piece with a lot more machining, and I'm guessing it has a hidden gasket to seal the deal between it and the table.

Flood coolant is such a royal PITA.

Sent from my Pixel XL using Tapatalk

Flood coolant is such a royal PITA.

Sent from my Pixel XL using Tapatalk