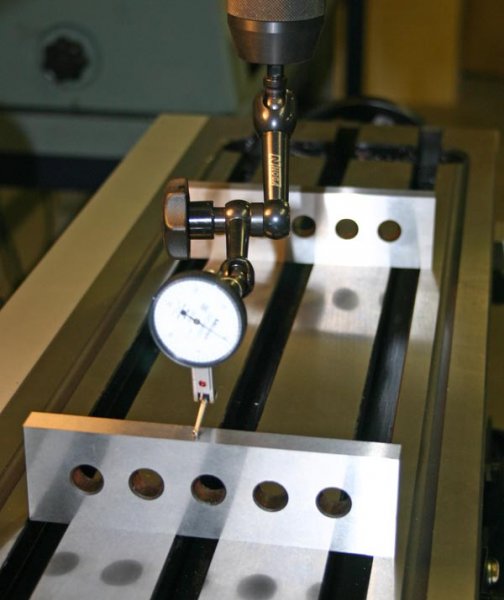

Looking for your collective wisdom on tramming techniques specific to this style of mill with 2 head rotations of freedom. I have initially set mine up 'with what I have' just to get going. Right now its +/- 0.0005" on all quadrants at about 6" sweep radius. I have seen those dual dial indicator thingamabobs, both homebrew & commercial. Do you like them? One thing that occurred to me is I could easily make a longer rotating sweep arm to use in the long table axis to magnify the tilt (ie make it more accurate). But in the cross travel direction you are kind of limited to the table width. Or at last I haven't seen setup pictures where a longer datum bar is placed across the table to extend the sweep radius. So +/- different hardware favorites, is what I am doing +/- the norm & accuracy level?

One thing I found in my procedure (which took a lot longer than I thought it would) is I got it to within a couple thou just using a dial indicator quite quickly, kind of roughing it in. But once I had the more accurate DTI on it, seemed like just breathing on it could move it in & out of tolerance & it became fiddly & time consuming. I found had to be careful about the tightening up phase because I could lose the position on that alone. I was usually within the dead band of the adjustment nut so trying to move that to a needle position just made matters worse over-shooting so to speak. I found I could just push & hold the head a bit to nudge the last thou. Is this fiddle-farting home stretch phase typical or any good techniques you can recommend?

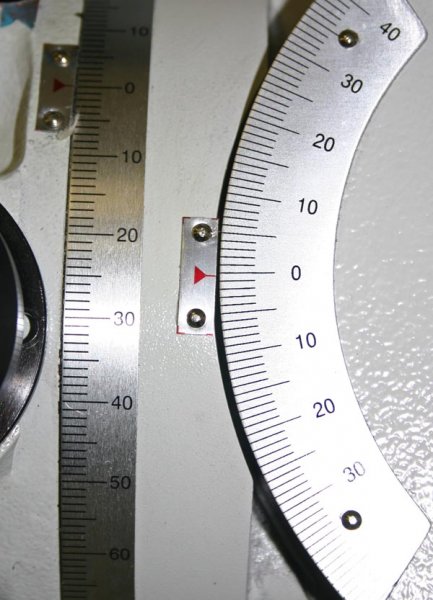

No real surprise my graduated plate does not line up to zero. I wish they had an adjustable mini plate to make the reference zero line up. I have that on my rotary table. Anyone modded something or do you just remove drive pins & reset if it really bothers you?

I purchased a dedicated 3/8" drive ratchet wrench with 19mm socket as my go-to tool for the various clamping nuts & adjuster jack screws. It was inexpensive & has a bright handle! Are you guys using torque wrenches to avert over tightening or does this operation fall under common sense, don't gronk on it & short 6" handle kind of limits how much torque is applied. I haven't run the machine long enough to know if mine holds position quite yet.

One thing I found in my procedure (which took a lot longer than I thought it would) is I got it to within a couple thou just using a dial indicator quite quickly, kind of roughing it in. But once I had the more accurate DTI on it, seemed like just breathing on it could move it in & out of tolerance & it became fiddly & time consuming. I found had to be careful about the tightening up phase because I could lose the position on that alone. I was usually within the dead band of the adjustment nut so trying to move that to a needle position just made matters worse over-shooting so to speak. I found I could just push & hold the head a bit to nudge the last thou. Is this fiddle-farting home stretch phase typical or any good techniques you can recommend?

No real surprise my graduated plate does not line up to zero. I wish they had an adjustable mini plate to make the reference zero line up. I have that on my rotary table. Anyone modded something or do you just remove drive pins & reset if it really bothers you?

I purchased a dedicated 3/8" drive ratchet wrench with 19mm socket as my go-to tool for the various clamping nuts & adjuster jack screws. It was inexpensive & has a bright handle! Are you guys using torque wrenches to avert over tightening or does this operation fall under common sense, don't gronk on it & short 6" handle kind of limits how much torque is applied. I haven't run the machine long enough to know if mine holds position quite yet.

Last edited: