- Joined

- Jan 9, 2013

- Messages

- 1,020

When I got my used 10-22 I just knew that that must be big enough for the size of what I planned to do, (telescope parts). As soon as I started

to learn just how to use a lathe I discovered that some of my parts while being under 10" in diameter, wouldn't fit in a chuck and turn a 10" dia.

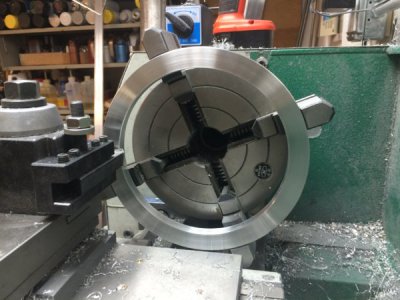

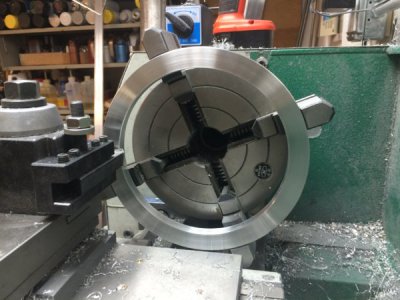

part, duh. Neither my 3 or 4 jaw chucks would hold an item that was that large. My 4 jaw when fully opened (too far for safety) would seriously

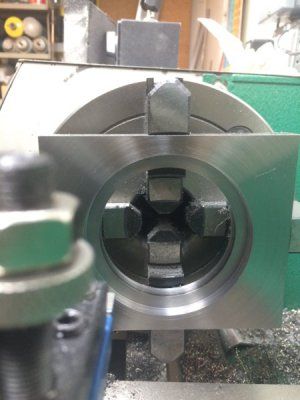

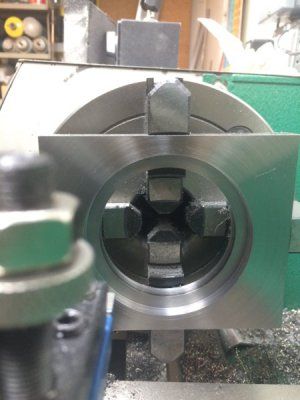

run into the ways and still wouldn't hold a 10 dia. part. Oh well, just chalk it up to a learning experience. Then it dawned on me to remove the

jaws completely and mount the plate directly to the face of the chuck body. I could bolt it or.....tape it with double sided 3M tape. Hold the part

against the chuck with a live center and there you go. The biggest problem is removing the part from the chuck tape, but a little heat seemed to

do it. Who needs a stinkin' big lathe? (well maybe I do, but...) I've used this method forever 40 similar parts with nary a hitch. I only use my 4 jaw

chuck, independent jaw not scroll, for holding other than round or square, like rectangular parts that are too big for my 3 jaw but not large enough

to use the tape method.

CHuck the grumpy (but still learning) old guy,

to learn just how to use a lathe I discovered that some of my parts while being under 10" in diameter, wouldn't fit in a chuck and turn a 10" dia.

part, duh. Neither my 3 or 4 jaw chucks would hold an item that was that large. My 4 jaw when fully opened (too far for safety) would seriously

run into the ways and still wouldn't hold a 10 dia. part. Oh well, just chalk it up to a learning experience. Then it dawned on me to remove the

jaws completely and mount the plate directly to the face of the chuck body. I could bolt it or.....tape it with double sided 3M tape. Hold the part

against the chuck with a live center and there you go. The biggest problem is removing the part from the chuck tape, but a little heat seemed to

do it. Who needs a stinkin' big lathe? (well maybe I do, but...) I've used this method forever 40 similar parts with nary a hitch. I only use my 4 jaw

chuck, independent jaw not scroll, for holding other than round or square, like rectangular parts that are too big for my 3 jaw but not large enough

to use the tape method.

CHuck the grumpy (but still learning) old guy,