- Joined

- Nov 24, 2013

- Messages

- 1,791

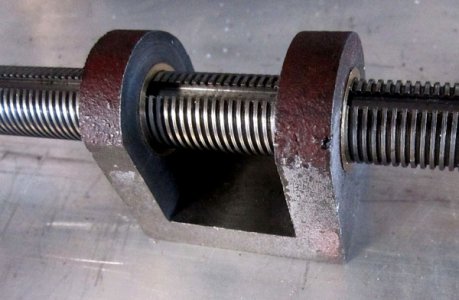

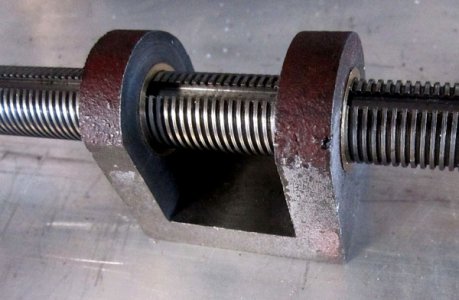

That small gear is part of the shaft. It only cost 20 bucks or so.

Not your fault. The factory did not do their homework building these machines. I rebuilt the apron on mine twice before I redesigned it.

"Billy G"

I have a Sheldon now and when it is restored the Jet will become a back up lathe.

"Billy G"

Charles, is it the shaft these gears are on that is bent?

Is it soft enough to bore out the centre and make a new shaft to fit in? Let me know if I can help with anything

Cheers Phil